Dredging & Civil Construction

Extensive Dredging Expertise

Neumann Dredging stands as a preeminent leader in the dredging industry, boasting an impressive legacy spanning over seventy years in both maintenance and mining dredging sectors.

Our seasoned team of specialists is equipped with profound skills, comprehensive knowledge, and advanced equipment to proficiently handle dredging projects of diverse magnitudes and intricacies. Whether it’s preserving navigable waterways or extracting valuable minerals, our innovative and eco-friendly methodologies ensure superior outcomes.

Neumann Dredging: Your definitive partner for comprehensive dredging solutions.

A Rich Heritage in Dredging

Our journey, extending beyond six decades in the dredging field and over seventy years in operational excellence, showcases Neumann Dredging’s commitment to tackling Australasia’s most challenging dredging tasks.

Renowned for our innovative, cost-effective solutions and technical prowess, we’ve built an enviable reputation for quality and reliability.

With a vast portfolio of successful projects, we consistently surpass client expectations.

Holistic Dredging Solutions

Neumann Dredging has been delivering comprehensive dredging services across a myriad of projects in Australasia. Our expert team not only designs and maintains but also operates our proprietary dredging equipment. Our expertise extends to creating specialised winches and winching equipment for industries including mining, marine, hire, and communications.

Our in-house control over equipment design and manufacturing allows us to swiftly adapt and innovate, perfectly aligning with the unique demands of any dredging project.

Dredge and booster pump hire

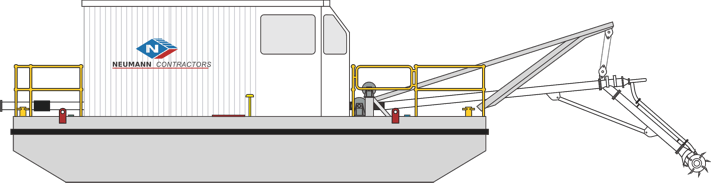

Our Cutter Suction Dredges and Booster Pumps are available for hire, offering high-quality, reliable, and cost-efficient dredging solutions.

We handle everything in-house, from building to servicing and overhauling the equipment. Our dry-hire option includes an initial training period for your staff, with a range of dredges, booster pumps, and piping from 250mm to 500mm.

Rely on Neumann Dredging for the ideal equipment and expert guidance for your dredging needs.

Unmatched Reliability and Dependability

Neumann Dredging has been an integral part of the dredging sector for over seven decades, demonstrating an unmatched success rate.

Our collaborative approach with clients, combined with our commitment to innovation and tailored solutions, underpins our operations. As a member of a robust family of companies, we pride ourselves on solving complex challenges and fulfilling our promises.

Choose Neumann Dredging, where reliability meets innovation.

Tailings Dredging Excellence

Neumann Dredging is your go-to expert for tailings dredging, leveraging our extensive experience, technological advancement, and unwavering commitment to quality.

We offer bespoke solutions that are both efficient and effective, backed by our cutting-edge equipment and in-house engineering expertise.

Safety and environmental responsibility are at the forefront of our operations, making us the optimal choice for your tailings dredging projects.

Channel Maintenance Dredging

Neumann Dredging is your ideal choice for channel maintenance dredging, distinguished by our vast industry experience, highly skilled professionals, and innovative technologies.

We understand the critical nature of waterway maintenance for efficient transport and are dedicated to delivering dependable, cost-effective dredging solutions. With a fleet of advanced equipment and a history of successful Australasian projects, Neumann Dredging is your trusted partner for channel maintenance dredging.

Featured Dredging Projects

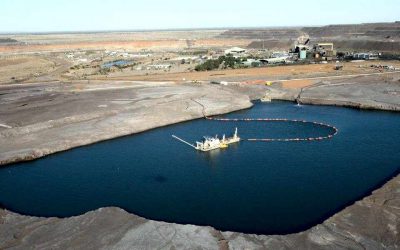

Ernest Henry Mine Tailings Dredging

Tailings Removal/Transfer,

Tailings Reprocessing,

Re-Mining.

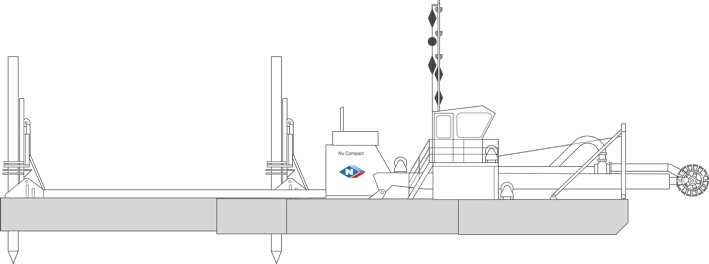

Ernest Henry Mining commissioned our 300mm CSD Nu Compact to reprocess/remine the tailings from the Tailings Storage Facility (TSF) to recover magnetite. The Nu Compact pumped the reclaimed tailings via a 1000 metre long HDPE pipeline directly into a processing circuit in which the magnetite was concentrated. The dredge operated on a 24/ basis while maintaining a consistent feed density to the processing plant.

Hellyer Gold Dredge Hire

Dredge Dry Hire,

Mud/Silt/Sediment Removal / Relocation.

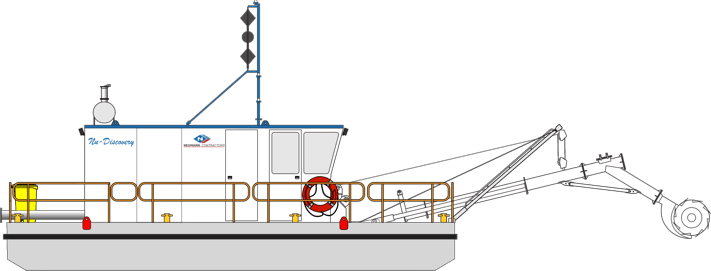

Hellyer Gold Mines hired a Neumann Contractors' designed and built 250mm cutter suction dredge, the ‘Nu-Investigator’ for 12 months to supplement the operations of their existing dredge in the site's tailings ponds. The hire agreement was a dry hire arrangement with Neumann Contractors providing experienced operators in the initial phase to train Hellyer’s operators in running the dredge.

Sydney Water Desalination Project

Capital Works Dredging,

Ports and Harbour,

River and Waterways Dredging.

Dredging works associated with the Botany Bay pipeline crossing, which was part of the construction of Sydney’s DeSal plant at Kurnell, Southern Sydney. When completed water from the desalination plant will be piped to the City Water Tunnel at Erskineville. This is part of the Potts Hill Water system, which services areas south of Sydney Harbour, to Bankstown in the west and Sutherland in the south.

Kingscoast Estate Project

Resource Mining,

Hydraulic Sand Transfer,

Civil Works.

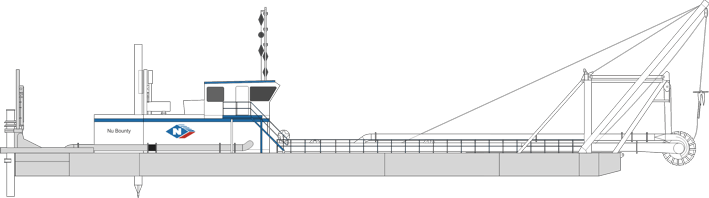

The project was to hydraulically place 370,000 m3 of sand to raise the surface level of the Kingscoast Estate by 3 metres. The team dredged the sand from an adjacent sand quarry by the Nu Bounty, a 450mm bucketwheel cutter suction dredge combined with a 500mm, 2,000 hp booster pump. The slurry was pumped distances up to 2,000m through a 560mm poly pipeline to the estate. We achieved considerable savings and advantages over traditional methods.

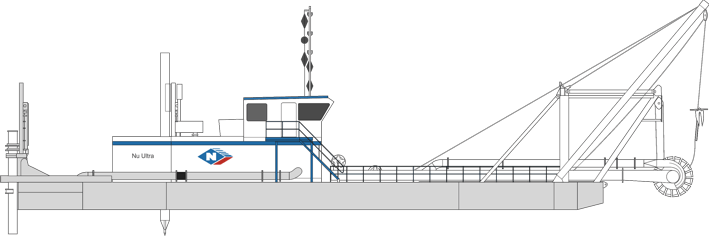

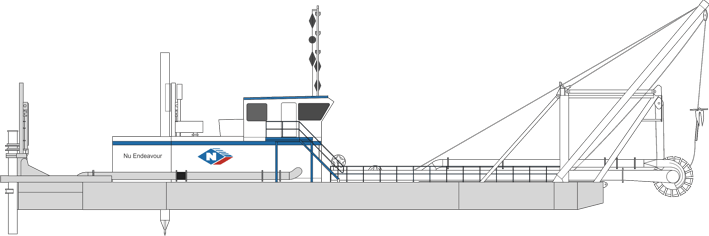

Cutter Suction Dredges in Our Fleet

100% Australian Owned

More than 70 Years Dredging Experience

Innovation

Neumann Dredging has a reputation for completing demanding dredging projects by utilising over 70 years of experience, highly qualified staff, engineering expertise and innovation to provide cost-effective solutions to overcome challenges.

Safety

Neumann Dredging is committed to having a safe and healthy work environment for all team members and all associated others. The continuous improvement of our occupational health and safety in our dredging and associated activities are our utmost priority.

Quality

Neumann Dredging has a comprehensive Quality Management System in place. We customise the system to suit each dredging project we undertake to deliver quality outcomes and satisfy our clients' standards and project specifications.

Environment

Neumann Dredging is continuing to meet the challenges of sustainable construction practices in the twenty-first century. Our solid relationships with both expert consultants and regulators are based on a unique approach to meeting the goals of each project.

Providing Innovative Dredging Solutions for:

Client: HQ Sands, Repton, New South Wales, Australia.

Works Categories: Sand Mining, Rivers and Waterways, Dredge Hire.

Materials Dredged: Clean Sand, Coarse Sand, Sediments, Silts.

Client: Bhagwan Marine, Murarries, Queensland, Australia.

Categories: Navigational Channel Maintenance, Rivers and Waterways Dredging, Ports and Harbours Dredging, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: BMA - BHP Mitsubishi Alliance, Brisbane, Queensland, Australia.

Categories: Mud / Silt / Sediment Removal / Relocation.

Materials Dredged: Mud, Cobbles, Sediments, Silts.

Client: AGL Energy, Australia.

Works Categories: Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Fly Ash.

Client: Penrith Lakes Development Corporation, New South Wales, Australia.

Works Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Ports Authority of New South Wales, Australia.

Work Categories: Capital Works Dredging, Ports and Harbours, Navigational Channel Maintenance, Rivers and Waterways,

Materials Dredged: Sand, Silts, Sediments.

Client: Multiplex, Headquarters in Sydney, New South Wales, Australia.

Categories: Capital Works Dredging, Rivers and Waterways Dredging, Reclamation, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Department of Transport and Main Roads, Queensland, Australia.

Categories: Navigational Channel Maintenance, River and Waterways Dredging, Coastal Protection / Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Mid Coast Council, New South Wales, Australia.

Categories: Navigational Channel Maintenance Dredging, Rivers and Waterways Dredging, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Quarry Solutions, Evans Head, New South Wales, Australia.

Categories: Resource Dredging, Sand Mining.

Materials Dredged: Clean Sand, Coarse Sand, Sediments, Silts.

Client: Corridor Sands, Woongoolba, Queensland, Australia.

Categories: Resource Dredging, Sand Mining, Dredge Hire.

Materials Dredged: Clean Sand, Coarse Sand, Sediments, Silts.

Client: Gold Coast Waterways Authority, Queensland, Australia.

Categories: Navigational Channel Maintenance, Rivers and Waterways Dredging, Reclamation, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Port of Townsville, Queensland, Australia.

Categories: Ports and Harbours Dredging, Navigational Channel Maintenance, Rivers and Waterways Dredging.

Materials Dredged: Clay, PASS, Clean Sand, Sediments, Silts.

Client: Department of Finance and Services for Trade and Investment, New South Wales, Australia.

Works Categories: Navigational Channel Maintenance, Rivers and Waterways, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Gold Coast City Council, Queensland, Australia.

Categories: Navigational Channel Maintenance, Rivers and Waterways Dredging, Reclamation, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: CABP Group Pty Ltd, Raymond Terrace, New South Wales, Australia.

Works Categories: Resource Dredging, Sand Mining.

Materials Dredged: Clean Sand, Coarse Sand, Sediments, Silts.

Client: Xstrata Copper, Queensland, Australia. Ernest Henry Mine

Works Categories: Tailings Reprocessing, Resource Dredging, Tailings Dredging.

Materials Dredged: Magnetite Tailings.

Client: Superior Coal, Brisbane, Queensland, Australia. Limited

Categories: Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Coal Tailings, Mud, Sediments, Silts.

Client: FKG Group, Brisbane, Queensland, Australia.

Works Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Mud, Sediments, Silts.

Client: Hellyer Gold Mines, Tasmania, Australia.

Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance, Dredge Hire

Materials Dredged: Mud, Sediments, Silts.

Client: Ok Tedi Mining, Papua New Guinea.

Works Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Tailings, Mud, Sediments, Silts.

Client: Bayside City Council, New South Wales, Australia.

Works Categories: Coastal Protection / Beach Nourishment, Hydraulic Sand Transfer.

Materials Dredged: Clean Sand, Coarse Sand, Sediments, Silts.

Client: Iluka, Offices in Australia

Work Categories: Resource Dredging, Sand Mining.

Materials Dredged: Clean Sand, Mineral Sands, Fine Sand, Coarse Sand.

Client: BHP Billiton, Headquarters in Melbourne, Victoria, Australia. Limited

Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Mud, Sediments, Silts.

Client: Newcrest Mining, Headquarters in Melbourne, Victoria, Australia. Limited

Categories: Mud / Silt / Sediment Removal / Relocation, Tailings Storage Facility (TSF) Maintenance.

Materials Dredged: Mud, Sediments, Silts.

Client: MCB Partnership - Water Delivery Alliance - Sydney Water, New South Wales, Australia.

Categories: Capital Works Dredging, Ports and Harbours Dredging, Rivers and Waterways Dredging.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Gladstone Ports Corporation, Gladstone, Queensland, Australia.

Capital Works, Ports and Harbours, Navigational Channel Maintenance, Rivers and Waterways,

Materials Dredged: Sand, Silts, Sediments.

Client: Synergy Resource Management, Bundall, Gold Coast, Queensland, Australia.

Works Categories: Navigational Channel Maintenance, Rivers and Waterways.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Sunshine Coast Council, Queensland, Australia.

Works Categories: Navigational Channel Maintenance, Rivers and Waterways, Beach Nourishment.

Materials Dredged: Clean Sand, Sediments, Silts.

Client: Glencore Commodity Company, Offices in Brisbane, Queensland, Australia.

Categories: Tailings Removal / Relocation, Mud Removal / Relocation

Material Dredged: Coal Tailings, Mud, Silt.

and many more...

Client Feedback

South Wavebreak Island Channel

Navigational Channel Maintenance, Beach Nourishment.

“Please pass on my thanks to your team. They did a great job, accommodated all our requests to board the vessel, provided quality feedback to Emma’s environmental questions and did the job quickly and efficiently which minimised impact to the stakeholders.

Additionally, the change you proposed to the placement methodology (going south to north) was the correct approach. I’m very glad we did not go north to south.

I look forward to working with Neumann’s in the future on other campaigns.”

Peter

Ramsgate Baths Project

Beach Nourishment, Replenishment Works, Hydraulic Sand Transfer,

“Thanks for arranging the quick collection of the Protective Fencing around the above Works and I am pleased to advise the Baths were reopened to the Public on Thursday. In fact, the Public were waiting just behind your Contractors so as soon as the last panels were removed, they charged into the Pool Area.

I wish to thank you and especially Josh for undertaking this project which have been overwhelming endorsed by the Public. I have received nothing but compliments from the Public and our Councillors on this Project.

Unfortunately, I could not hold you here for more works once you were set up but now knowing how long it takes to set up hopefully in the not too distant future we can engage Neumann Dredging again for further beach nourishment works along our foreshore.”

Colin

Kinross Estate - Stage 9

ReclamationWorks, Hydraulic Sand Transfer, Civil Works, Capital Works.

“On time with no operational management issues during the works. Very easy contractor to manage as communication was forthcoming and easy. The contract was completed ahead of contracted schedule.

Open, frank and transparent communication made the optimum solution possible.”

Paul

More Information on Neumann Dredging Services

Maximizing Resources with Tailings Dredging – Neumann Dredging

Mining has played a crucial role in the development of human civilization, but it comes with its own set of challenges. One of the significant challenges in mining operations is the management of tailings, which are the waste materials left over after extracting valuable minerals from ore. These tailings contain harmful chemicals, including heavy metals, which can have severe environmental consequences if not properly managed. Neumann Dredging is a leading expert in tailings dredging, providing innovative solutions for the mining industry to ensure responsible and sustainable tailings management.

What is Tailings Dredging?

Tailings dredging involves the removal of tailings from tailings dams, ponds, or impoundments using dredging equipment. Tailings dams are large structures used to store tailings, which can accumulate over time and become unstable, posing a significant risk to the environment and human health. Dredging allows removing these tailings, which can be treated or disposed of safely.

The Importance of Tailings Dredging in Mining Operations

Mining operations generate a significant amount of tailings, and proper management of tailings is crucial to ensure the sustainability of mining operations. Tailings dams can be hazardous, and if they fail, they can release large volumes of contaminated water and waste materials, causing significant environmental damage and risking the health and safety of nearby communities. Tailings dredging helps reduce the risks associated with tailings storage and ensures that mining operations are sustainable.

Neumann Dredging’s Expertise in Tailings Dredging

Neumann Dredging has extensive experience in tailings dredging, providing innovative solutions to the mining industry. The company has a range of dredging equipment, including cutter suction dredgers, which can efficiently remove large volumes of tailings. Neumann Dredging also offers a range of other services, including designing and constructing tailings dams, dewatering of tailings, and reclamation of tailings storage areas.

Neumann Dredging’s Tailings Dredging Process

Neumann Dredging follows a systematic and efficient tailings dredging process, which includes the following steps:

- Site Inspection and Assessment: The first step in tailings dredging is to conduct a site inspection and assessment to determine the most appropriate dredging method and equipment.

- Dredging: Once the site assessment is completed, Neumann Dredging deploys its dredging equipment to remove the tailings. The company’s cutter suction dredgers are designed to remove large volumes of tailings efficiently and effectively.

- Transport and Disposal: After the tailings are dredged, they are transported to a processing facility or a tailings storage facility for treatment or disposal. Neumann Dredging has the expertise and experience to ensure tailings are transported safely and efficiently.

- Site Restoration: Once the tailings have been removed, the mining company restores the site to its original condition, including re-vegetation, erosion control, and slope stabilization.

Benefits of Neumann Dredging’s Tailings Dredging Services

Neumann Dredging’s tailings dredging services provide numerous benefits to mining companies, including:

- Sustainable Tailings Management: Neumann Dredging’s tailings dredging services ensure that tailings are managed sustainably, reducing the environmental impact of mining operations.

- Increased Safety: Tailings dams can be hazardous, and proper tailings management is crucial for ensuring the safety of nearby communities. Neumann Dredging’s tailings dredging services help reduce the risks associated with tailings storage.

- Cost-Effective: Tailings dredging can be a cost-effective solution for mining companies, as it allows for reprocessing valuable minerals that may have been missed during the initial extraction process. By removing tailings, companies can also reduce the costs associated with maintaining and managing tailings dams.

- Improved Environmental Compliance: Neumann Dredging’s tailings dredging services ensure that mining companies comply with environmental regulations and best practices for tailings management. This reduces the risk of environmental damage and helps maintain the company’s social license to operate.

Tailings dredging is an essential part of responsible and sustainable mining operations. It helps reduce the risks associated with tailings storage and ensures that mining operations are conducted safely and responsibly. Neumann Dredging’s expertise in tailings dredging provides mining companies with innovative solutions to manage their tailings effectively and sustainably while reducing costs and improving environmental compliance. As the mining industry continues to grow and evolve, it is crucial to prioritize responsible and sustainable tailings management. Neumann Dredging is well-equipped to help mining companies meet this challenge.

Clearing the way for safe navigation – Neumann Dredging

Waterways play an important role in transportation and the movement of goods. To ensure that these waterways remain navigable, regular maintenance dredging is necessary. Neumann Dredging, based in Australia, offers channel maintenance dredging services using a cutter suction dredge. In this blog post, we will explore the benefits of this method and how Neumann Dredging utilises it.

What is Cutter Suction Dredging?

Cutter suction dredging is a method of dredging that involves a cutter head at the end of a suction pipe. The cutter head rotates and cuts through the sediment while the suction pipe pumps the material into a hold or hopper for disposal. This method is efficient and effective for removing large volumes of sediment from waterways.

Why Use Cutter Suction Dredging for Channel Maintenance?

Sediment buildup can reduce the depth of waterways, making navigation difficult or impossible for large vessels. Maintenance dredging using a cutter suction dredge can remove the sediment and restore the necessary depth for safe navigation. This method is also environmentally friendly, as it minimises the disturbance of surrounding habitats.

How Does Neumann Dredging Utilize Cutter Suction Dredging for Channel Maintenance?

Neumann Dredging uses state-of-the-art cutter suction dredges for channel maintenance. These dredges are equipped with the latest technology, such as GPS positioning and monitoring systems, to ensure accurate and efficient dredging. Neumann Dredging also employs experienced and highly skilled operators to operate the dredges and ensure that the dredging is done safely and efficiently.

Benefits of Neumann Dredging’s Cutter Suction Dredging Services

Neumann Dredging’s cutter suction dredging services offer several benefits.

- They can remove large volumes of sediment quickly and efficiently, allowing for minimal disruption to navigation.

- They are environmentally friendly and do not harm surrounding habitats.

- Neumann Dredging’s use of advanced technology and experienced operators ensures that the dredging is done safely and effectively.

Maintaining navigable waterways is essential for transportation and commerce. Cutter suction dredging is an efficient and effective method for removing sediment and maintaining waterway depths. Neumann Dredging’s use of state-of-the-art cutter suction dredges and experienced operators ensures their channel maintenance dredging services are safe, efficient, and environmentally friendly.

Unearth the Potential with Neumann Dredging

Resource dredging is an essential process in the mining industry that involves the removal of sediments or minerals from water bodies or seabeds. This process is crucial for efficiently extracting valuable resources, as it increases the productivity of mining operations. Neumann Dredging is a leading expert in resource dredging, providing innovative solutions to the mining industry to maximize resource extraction.

What is Resource Dredging?

Resource dredging removes sediments, minerals, and other materials from the seabed or water bodies using a dredge. A dredge is a machine that extracts materials from the bottom of water bodies by suction, cutting, or lifting. Resource dredging can be used to extract various resources, including sand, gravel, and minerals.

The Importance of Resource Dredging in Mining Operations

Resource dredging plays a crucial role in the mining industry, as it enables the extraction of valuable resources that would otherwise be difficult to access. Dredging allows mining companies to increase their productivity by accessing previously inaccessible resources. It also helps to reduce the environmental impact of mining operations by minimising the disturbance to the surrounding ecosystem.

Neumann Dredging’s Expertise in Resource Dredging

Neumann Dredging has extensive experience in resource dredging, providing innovative solutions to the mining industry. The company has a range of dredging equipment, including cutter suction dredgers, which can efficiently remove large volumes of sediments and minerals. Neumann Dredging also offers a range of other services, including designing and constructing tailings dams, dewatering of tailings, and reclamation of tailings storage areas.

Benefits of Neumann Dredging’s Resource Dredging Services

Neumann Dredging’s resource dredging services provide numerous benefits to mining companies, including:

- Increased Productivity: Resource dredging enables mining companies to access previously inaccessible resources, increasing their productivity and profitability.

- Reduced Environmental Impact: Resource dredging helps to minimize the disturbance to the surrounding ecosystem, reducing the environmental impact of mining operations.

- Efficient Resource Extraction: Neumann Dredging’s resource dredging process is designed to remove sediments and minerals efficiently and effectively, ensuring the efficient extraction of resources.

- Cost-Effective: Resource dredging can be a cost-effective way to extract resources, particularly when compared to other extraction methods.

Resource dredging is an essential process in the mining industry that enables the extraction of valuable resources. Neumann Dredging’s expertise in resource dredging provides innovative solutions to mining companies, helping them to maximize their productivity while minimizing their environmental impact. With its efficient and cost-effective resource dredging process, Neumann Dredging is a trusted partner for mining.

Maintaining your waterway, maintaining your livelihood – Neumann Dredging

Introduction: Channel maintenance dredging is the process of removing accumulated sediment and debris from a waterway to ensure safe and efficient navigation. It is a critical aspect of maritime infrastructure and plays a vital role in maintaining safe and navigable waterways. In this article, we will explore the importance of channel maintenance dredging and the benefits it provides to the environment, commerce, and public safety.

Why is Channel Maintenance Dredging Important?

Ensuring Safe Navigation: Sediment accumulation is a natural process in waterways and can reduce the waterway’s depth, making it difficult for vessels to navigate. This can be a serious problem for commercial vessels, as they rely on navigable waterways to transport goods and services. Dredging helps maintain the channel’s depth and width, ensuring safe and efficient navigation for vessels of all sizes.

Preventing Environmental Disasters: Sediment accumulation can also have a detrimental impact on the environment. When sediment is allowed to build up, it can lead to reduced water quality, as the sediment contains pollutants and contaminants. Dredging helps to remove these pollutants, improving water quality and preventing potential environmental disasters.

Supporting Local Economies: Commercial vessels play a significant role in the economy, and channel maintenance dredging is crucial in supporting their operations. By maintaining navigable waterways, dredging helps to facilitate the transportation of goods and services, supporting local economies and businesses.

Maintaining Public Safety: Maintaining safe and navigable waterways is critical for public safety. In emergency situations, such as natural disasters, vessels may need to navigate through waterways quickly and efficiently. Dredging helps to ensure that the waterways are clear and safe for vessels to navigate, reducing the risk of accidents and injuries.

In summary, channel maintenance dredging is crucial to maintaining safe and navigable waterways. It plays a vital role in supporting local economies, preventing environmental disasters, and maintaining public safety. As sediment accumulation is a natural process, regular dredging is necessary to ensure commercial vessels’ smooth and efficient operation and protect the environment. It is an investment that pays dividends in both the short and long term, benefiting the economy and the environment.

Partnering with the mining industry to uphold GISTM standards

The mining industry is vital to global economic development, but it also presents significant environmental challenges. Tailings management is one of the critical challenges in the mining industry. The Global Industry Standard on Tailings Management (GISTM) was launched in 2020 to promote the responsible management of tailings. Neumann Dredging, a leading expert in tailings dredging, has taken an active role in the adoption and implementation of the GISTM, providing innovative and sustainable solutions for the mining industry.

What is the Global Industry Standard on Tailings Management (GISTM)?

The GISTM is a global standard for the responsible management of tailings, developed by the United Nations Environment Programme, Principles for Responsible Investment, and the International Council on Mining and Metals. The GISTM provides a framework for managing tailings throughout the entire life cycle of a mine, from the design and construction of tailings facilities to their closure.

How does the GISTM relate to Neumann Dredging?

Neumann Dredging has been actively involved in the adoption and implementation of the GISTM, recognizing the importance of responsible and sustainable tailings management. The company has been providing innovative solutions for tailings dredging and management, contributing to the goal of achieving the GISTM’s principles of safety, environmental protection, and community engagement.

Neumann Dredging’s sustainable approach to mining operations

Neumann Dredging’s sustainable approach to mining operations aligns with the principles of the GISTM. The company provides innovative solutions for tailings dredging, which reduces the risks associated with tailings storage and ensures that mining operations are sustainable. Neumann Dredging’s tailings dredging services help reduce the environmental impact of mining operations, promoting the responsible management of tailings.

Adoption and implementation of the GISTM by Neumann Dredging

Neumann Dredging has taken an active role in the adoption and implementation of the GISTM, recognizing the importance of responsible tailings management. The company has integrated the GISTM’s principles into its operations, including site assessment, dredging, transportation, disposal, and site restoration. Neumann Dredging’s tailings dredging process is aligned with the GISTM’s principles of safety, environmental protection, and community engagement.

Benefits of adopting the GISTM for mining operations Adopting the GISTM can bring numerous benefits to mining operations, including:

Improved safety: The GISTM promotes the design and construction of tailings facilities that are safe and stable, reducing the risk of tailings dam failures and ensuring the safety of nearby communities.

Environmental protection: The GISTM promotes the responsible management of tailings, reducing the environmental impact of mining operations and protecting ecosystems.

Community engagement: The GISTM encourages mining companies to engage with communities and stakeholders, promoting transparency, accountability, and social responsibility.

The adoption and implementation of the GISTM are critical to promoting responsible and sustainable tailings management in the mining industry. Neumann Dredging’s sustainable approach to mining operations aligns with the GISTM’s principles of safety, environmental protection, and community engagement. By providing innovative solutions for tailings dredging and management, Neumann Dredging is contributing to the goal of achieving the GISTM’s principles and ensuring that mining operations are responsible and sustainable.

Keeping your channels clear and navigable – Neumann Dredging

Australia is home to some of the most stunning coastlines in the world, attracting millions of visitors every year. However, the constant battering of waves and changing tides can result in erosion, threatening the natural beauty and the long-term resilience of the coastline. Neumann Dredging is a leading dredging company that has been undertaking channel maintenance dredging and beach nourishment projects along the Australian coastlines, enhancing their beauty and resilience. This essay delves into the importance of these projects and how Neumann Dredging is contributing to protecting Australia’s coasts.

Importance of Channel Maintenance Dredging and Beach Nourishment Projects:

Channel maintenance dredging is the process of removing sediment buildup from channels, estuaries, and ports, ensuring they remain navigable for vessels. The process involves the use of dredging equipment, such as a cutter suction dredge, to remove sediment and debris from the bottom of the waterways. This process is crucial for maintaining the safe passage of commercial and recreational vessels, preventing flooding and erosion, and ensuring the continuity of supply chains.

On the other hand, beach nourishment is the process of adding sand or sediment to eroding beaches, helping to restore their natural beauty and protecting them from the effects of erosion. This process is essential for maintaining the tourism industry, protecting homes and businesses located along the coast, and preserving the natural environment.

Neumann Dredging’s Contribution:

Neumann Dredging has been at the forefront of channel maintenance dredging and beach nourishment projects along the Australian coastline for many years. Their team of highly experienced professionals utilizes state-of-the-art dredging equipment and innovative solutions to deliver effective and efficient dredging services that exceed the expectations of their clients.

One notable project was the Maroochy Dredging and Beach Nourishment Project. It was a comprehensive approach to addressing the issues facing the Maroochy River and its surrounding beaches. The project involved using a cutter suction dredge to remove sediment from the river channel and an excavator to deposit sand onto the beaches. The dredging component of the project focused on removing sediment buildup in the river channel, improving water quality and navigability for boaters and fishers. The beach nourishment component involved the placement of sand onto eroded beaches, restoring the natural balance of the coastal ecosystem. The Maroochy Dredging and Beach Nourishment Project had a range of benefits for the local community and environment. By removing accumulated sediment from the river channel, the project improved water quality and navigability, making the river safer and more accessible for boaters and anglers. The placement of sand onto eroded beaches helped protect against further erosion, maintaining the natural balance of the beach ecosystem. The project also had significant economic benefits for the region. By maintaining the health of the Maroochy River and its beaches, the project helped to support local tourism and recreation industries, which are critical drivers of the local economy.

Another project was the Swansea Channel Dredging and Beach Nourishment Project. The Swansea Channel is a significant New South Wales, Australia waterway connecting the Pacific Ocean to Lake Macquarie. Over the years, coastal erosion and sediment buildup have reduced the channel’s depth, causing navigational issues for boaters and potential safety hazards. Neumann Dredging, one of the leading dredging companies in Australia, was contracted to undertake a dredging and beach nourishment project to address these issues. The City of Lake Macquarie initiated the Swansea Channel dredging and beach nourishment project, with funding provided by the Australian Government’s National Stronger Regions Fund. The project aimed to increase the channel’s depth and improve its navigability while also addressing the issue of beach erosion. Neumann Dredging was tasked with dredging the channel’s entrance and pumping the sand onto Blacksmiths Beach, which had suffered severe erosion. The dredging and beach nourishment project involved using a cutter suction dredge to remove the accumulated sand and silt. A booster pump was also used to pump the sand the long distance to the beach.

Channel maintenance dredging and beach nourishment projects are crucial for the beauty and resilience of Australia’s coastlines. Neumann Dredging has been at the forefront of these projects, delivering innovative and efficient dredging solutions that protect the coastlines, the environment, and the local economy. By ensuring that the coastlines remain navigable, safe, and beautiful, Neumann Dredging plays a significant role in preserving Australia’s coastal communities’ natural beauty and economic viability.

Maximum Efficiency in Mining Dredging: Neumann Dredging

Mining dredging is an essential process that ensures a continuous supply of minerals to meet the ever-growing demand of industries worldwide. It involves removing unwanted materials that obstruct extracting valuable minerals from the earth. Mining dredging can be challenging and delicate, so it is essential to work with an experienced and reliable dredging company like Neumann Dredging.

What is Dredging?

Dredging is the process of excavating underwater materials from water bodies such as rivers, lakes, and oceans. This process is done to maintain waterways, deepen channels, and remove unwanted materials from the bottom of water bodies. Dredging can also be used in mining to extract minerals from the earth.

What is Mining Dredging?

Mining dredging is the process of using specialised equipment to extract minerals from the earth. Mining dredging is used to extract precious metals such as gold and silver, industrial minerals like coal, and construction materials like sand and gravel. Neumann Dredging is a renowned mining dredging company specialising in tailings dredging in Australia.

The Importance of Mining Dredging

Mining dredging is a crucial process in the mining industry as it enables the extraction of minerals from the earth. Without mining dredging, accessing and extracting minerals buried deep in the ground would be challenging. Mining dredging helps to increase the efficiency of mining operations and reduces the environmental impact caused by mining.

The Need for Experienced and Reliable Dredging Companies

Mining dredging is a delicate process that requires specialised knowledge and expertise to execute successfully. This is why working with experienced and reliable dredging companies such as Neumann Dredging is crucial. Neumann Dredging has over 50 years of experience providing mining dredging services in Australia. The company has a team of highly trained and skilled professionals who offer cost-effective solutions to mining companies.

The Benefits of Working with Neumann Dredging

Neumann Dredging offers a wide range of benefits to mining companies that need mining dredging services. Some of these benefits include:

- Advanced Technology – Neumann Dredging uses advanced technology to execute mining dredging operations. The company uses modern equipment designed to handle various mining dredging tasks with precision. This ensures that mining companies achieve their goals efficiently and effectively.

- Environmental Commitment – Mining dredging can have a negative impact on the environment if not done correctly. This is why Neumann Dredging is committed to executing mining dredging operations in an environmentally friendly manner. The company uses eco-friendly and sustainable dredging methods to minimise the environmental impact caused by mining.

- On-time Delivery – Neumann Dredging offers project management services to ensure that mining dredging projects are delivered on time and within budget. The company has a team of project managers who work closely with clients to ensure all project requirements are met.

Mining dredging is an essential process in the mining industry as it enables the extraction of minerals from the earth. Mining dredging can be a challenging and delicate process, which is why it is crucial to work with experienced and reliable dredging companies such as Neumann Dredging. Neumann Dredging has over 50 years of experience in providing mining dredging services in Australia, and the company offers a wide range of benefits to mining companies.

Maintaining your waterways for a safer and more efficient transportation system – Neumann Dredging.

The Gold Coast, located in Queensland, Australia, is one of the most popular tourist destinations in the world. Its long, sandy beaches, clear waters, and tropical climate make it a paradise for tourists and locals alike. However, maintaining these beautiful beaches and waterways requires a significant amount of effort and investment, including channel maintenance dredging. In this essay, we will discuss the importance of channel maintenance dredging and Neumann Dredging’s project on the Gold Coast.

Importance of Channel Maintenance Dredging:

Channel maintenance dredging is essential for keeping waterways safe, navigable, and contaminant-free. Over time, sediment, debris, and other materials accumulate in channels, reducing their depth and hindering water flow. This can lead to various problems, such as increased flood risk, loss of navigability, and damage to marine habitats. Therefore, regular channel maintenance dredging is necessary to remove the accumulated sediment and debris and maintain the waterway’s health and functionality.

Neumann Dredging’s Project on the Gold Coast:

Neumann Dredging has been involved in several channel maintenance dredging projects on the Gold Coast. One of their notable projects was the dredging of the Tallebudgera Creek entrance in Burleigh Heads. The project involved the removal of approximately 40,000 cubic meters of sand from the creek entrance, which had accumulated due to a natural sand bypass system. The dredged sand was then transported and placed on nearby Burleigh Beach, helping to replenish its sand volume and prevent erosion.

In another project, Neumann Dredging was responsible for dredging the Currumbin Creek entrance. The project involved the removal of approximately 35,000 cubic meters of sand from the creek entrance, which had caused water flow restrictions and flooding during high tide events. The dredged sand was then transported and placed on Palm Beach, helping to improve the beach’s aesthetics and provide better protection against erosion.

Benefits of the Project:

The project had numerous benefits, including improving water flow and navigability, reducing flood risks, and providing beach nourishment. Additionally, the project helped to promote marine life by removing accumulated pollutants and debris from the waterways, enhancing the overall health and sustainability of the marine environment.

Conclusion:

In conclusion, channel maintenance dredging is essential for the health and sustainability of waterways, particularly in coastal areas such as the Gold Coast. Neumann Dredging’s project on the Gold Coast has demonstrated the importance of channel maintenance dredging, as well as its numerous benefits for the environment and community. With its expertise and experience in dredging, Neumann Dredging continues to contribute to the maintenance and protection of waterways in Australia, ensuring their longevity and accessibility for generations to come.

Leading the way in responsible tailings management with GISTM

Mining is an essential industry providing the necessary raw materials for various goods and services we rely on daily. However, mining also generates large amounts of waste, including tailings, which can have significant environmental and social impacts if not appropriately managed. The Global Industry Standard on Tailings Management (GISTM) was developed in response to the devastating tailings dam failures that occurred in recent years. This blog post will explore the GISTM and why it is crucial for the mining industry.

What is the GISTM?

The GISTM is a framework developed by a group of leading mining companies, investors, and civil society organizations that outlines best practices for managing tailings. The framework aims to ensure that tailings are managed safely, responsibly, and sustainably to prevent accidents, protect the environment and human life, and respect human rights.

The GISTM covers the entire tailings management life cycle, from design and construction to closure and post-closure. It provides guidance on key areas such as risk management, community engagement, and emergency preparedness and response. The framework includes six principles that companies must adhere to, including respecting human rights, conducting a comprehensive risk assessment, and ensuring effective communication and stakeholder engagement.

Why is the GISTM important?

The GISTM is essential for several reasons. First, it helps prevent tailings dam failures like those at the Mount Polley and Brumadinho mines. These failures resulted in significant environmental damage, loss of life, and financial costs, highlighting the urgent need for better tailings management practices.

Second, the GISTM provides a standardized approach to tailings management that can be implemented across the industry. This helps to promote consistency and transparency, making it easier for stakeholders to assess mining operations’ environmental and social impacts.

Third, the GISTM emphasizes the importance of engaging with local communities and respecting human rights. This is crucial, as mining operations can significantly impact the livelihoods and well-being of nearby communities.

Conclusion:

The GISTM is a critical step forward in improving tailings management practices across the mining industry. By providing a standardized framework for managing tailings, the GISTM can help to prevent tailings dam failures, promote transparency and accountability, and protect the environment and human life. Neumman Dredging is committed to implementing best practices in tailings management and is working to align its operations with the principles outlined in the GISTM. As a leader in tailings dredging, the company has an important role to play in promoting sustainable and responsible mining practices.

Clearing the way for smooth sailing – Neumann Dredging’s channel maintenance dredging

Neumann Dredging is a leading provider of dredging services in Australia, with a strong focus on channel maintenance dredging. With over 70 years of experience, the company has developed a reputation as a reliable and efficient provider of dredging services, with particular expertise in maintaining the navigational channels of ports and harbours.

The Importance of Channel Maintenance Dredging

Effective channel maintenance dredging is essential to ensure that ports and harbours remain safe and navigable for ships of all sizes. Over time, sediment and debris can accumulate in navigational channels, reducing the depth of the water and increasing the risk of vessels running aground or colliding with underwater obstructions.

Neumann Dredging recognizes the critical importance of channel maintenance dredging and has developed specialized equipment and techniques to provide efficient and effective dredging services. The company’s dredging vessels are equipped with advanced positioning and monitoring systems, allowing them to accurately measure the depth of the water and identify areas that require dredging.

The Benefits of Neumann Dredging’s Approach

Neumann Dredging’s approach to channel maintenance dredging offers a range of benefits over traditional dredging techniques. One significant advantage is the company’s ability to operate in confined spaces, such as ports and harbours, without disrupting shipping operations.

Another significant benefit of Neumann Dredging’s approach is its focus on environmental sustainability. The company has developed specialized dredging techniques that minimise the impact on marine ecosystems and reduce the amount of sediment that is removed from the water.

Specialized Equipment for Channel Maintenance Dredging

Neumann Dredging’s specialized equipment is another key factor in its ability to provide efficient and effective channel maintenance dredging services. The company’s fleet of dredging vessels includes a range of specialised equipment, including cutter suction dredges. Cutter suction dredges, in particular, are a critical tool in Neumann Dredging’s arsenal for channel maintenance dredging. These vessels use a rotating cutter head to loosen sediment on the seabed, which is then suctioned up and pumped into a holding area for disposal.

Neumann Dredging’s Experience in Channel Maintenance Dredging

Neumann Dredging has a wealth of experience in channel maintenance dredging and has worked on some of Australia’s largest ports and harbours. The company has successfully completed dredging projects in Brisbane, Townsville, Gladstone, and Newcastle.

In each of these projects, Neumann Dredging has demonstrated its expertise in channel maintenance dredging, providing efficient and effective services while minimizing the impact on the environment and local communities.

Neumann Dredging is a leader in the field of channel maintenance dredging, with a proven track record of delivering high-quality services across Australia. The company’s expertise in this area, combined with its specialized equipment and commitment to environmental sustainability, make it a trusted partner for port and harbour authorities seeking to maintain the navigability of their waterways.

Efficiently Managing Tailings for a Sustainable Future – Neumann Dredging

Neumann Dredging is a company that has carved a name for itself in the dredging industry. The company is dedicated to providing a wide range of services, including tailings dam dredging, dewatering, slurry and water management to the mining and heavy industrial sectors.

Australia’s mining industry is one of the largest in the world, and Neumann Dredging has built a reputation as one of the leading dredging contractors in the country. Our tailings dredging services are among the best in the industry, and we have the experience and expertise to offer a dedicated and efficient service.

Our senior management team comprises experienced professionals who understand the mining industry’s intricacies and complexities. We have the right equipment and knowledge to deliver tailor-made solutions for every project we undertake. We understand that every project differs and work collaboratively with our clients to identify bespoke, cost-effective, and safe solutions.

Our commitment to quality, safety, and the environment is second to none. We have comprehensive environmental, quality, and safety frameworks underpinning every project. Our team is well-versed in working in remote and highly regulated mine environments, ensuring that we comply with all regulations and industry standards.

Our tailings dam remediation services are a crucial aspect of our business. Tailings dams are designed to store the waste material generated during the mining process. However, these dams can be dangerous, leading to catastrophic failures if not adequately managed. Our tailings dam remediation services are designed to prevent these failures and ensure the dams are safe and secure.

In addition to tailings dam remediation, we also offer dewatering services. Dewatering is the process of removing water from a site to allow mining operations to occur. Our dewatering services are designed to be efficient, cost-effective, and environmentally friendly.

Slurry and water management are also essential aspects of our services. We have the expertise to manage and transport slurry and water safely and efficiently. We understand that slurry and water management can be challenging, but with our experience and knowledge, we can offer a dedicated and efficient service.

Water infrastructure is another critical aspect of our services. We have the equipment and knowledge to design, construct and maintain water infrastructure, including dams, pipelines, and treatment facilities. Our water infrastructure services are designed to be efficient, cost-effective, and environmentally friendly.

Neumann Dredging is a company dedicated to tailings dam remediation, dewatering, slurry and water management, and water infrastructure services to the mining and heavy industrial sectors. We are widely recognised as Australia’s best privately owned dredging contractor. Our tailings dredging draws on our experience working for some of Australia’s largest mining companies to offer a dedicated service. With our commitment to quality, safety, and the environment, we are the ideal partner for any mining project.

Innovation and technology combined for unparalleled dredging performance – Neumann Dredging’s cutter suction dredges

Dredging is an essential process for maintaining waterways, ports, and harbours. A cutter suction dredge is a specialized vessel used to remove sediments from the seabed or riverbed. Neumann Dredging is a leading company in designing, constructing, and operating cutter suction dredges. They have a proven track record of delivering high-quality, innovative solutions for dredging challenges. This paper will explore the key features and advantages of cutter suction dredges built by Neumann Dredging.

Key Features of Cutter Suction Dredges Built by Neumann Dredging:

Customized Designs: Neumann Dredging provides customized designs based on the specific requirements of its clients. They have a team of expert engineers who use the latest design software to create cutting-edge dredges that are efficient and effective.

Robust Construction: Cutter suction dredges built by Neumann Dredging are designed to withstand harsh operating conditions. They use high-quality materials such as marine-grade steel and durable coatings to ensure the longevity of their vessels.

Innovative Technologies: Neumann Dredging is at the forefront of developing innovative dredging technologies. They have incorporated features such as dynamic positioning, real-time monitoring, and remote control systems into their dredges to improve safety and efficiency.

Environmentally Friendly: Neumann Dredging is committed to minimizing the environmental impact of dredging operations. Their dredges are equipped with advanced sediment separation and filtration systems that reduce the amount of sediment released back into the water.

Advantages of Cutter Suction Dredges Built by Neumann Dredging:

High Capacity: Cutter suction dredges built by Neumann Dredging have a high dredging capacity, which allows them to remove large volumes of sediment quickly and efficiently.

Versatility: Cutter suction dredges can be used in a variety of dredging applications, including harbour deepening, land reclamation, and beach nourishment. Neumann Dredging’s dredges are designed to be versatile and adaptable to different types of dredging projects.

Cost-Effective: Cutter suction dredges built by Neumann Dredging are designed to be cost-effective. They use fuel-efficient engines designed to minimize downtime, reducing operating costs.

Safety: Neumann Dredging places a high priority on safety. Their dredges are designed with safety features such as fire suppression systems, emergency stop buttons, and alarms. They also provide comprehensive training to their crew members to ensure their vessels’ safe and efficient operation.

Cutter suction dredges built by Neumann Dredging are innovative solutions for dredging challenges. They provide customized designs, robust construction, innovative technologies, and environmentally friendly features. Their dredges have a high capacity, versatility, cost-effectiveness, and safety features. Neumann Dredging’s expertise in designing and building cutter suction dredges has made them a trusted partner for many clients in the dredging industry.

Protecting our planet with GISTM best practices

Tailings management is a critical aspect of the mining industry that involves appropriately handling and disposing of waste materials generated from mining operations. The Global Industry Standard on Tailings Management (GISTM) is a framework developed by a coalition of industry leaders, civil society organizations, and the United Nations Environmental Programme (UNEP) to enhance the safety, environmental and social performance of tailings facilities worldwide. This blog will explore the key points of the GISTM.

Section 1: The Purpose of GISTM

The purpose of the GISTM is to provide a global standard for tailings management that will help to prevent catastrophic failures and improve the overall performance of tailings facilities. The GISTM provides a comprehensive framework for managing tailings throughout their lifecycle, from design and construction to operation and closure.

Section 2: The Components of GISTM

The GISTM is composed of six components that provide guidance on the management of tailings facilities:

- Leadership and Accountability: This component emphasizes the need for strong leadership and accountability in managing tailings facilities. It recommends that companies establish clear lines of responsibility and accountability for tailings management and that senior management actively ensures that tailings facilities are designed, constructed, operated and closed safely and responsibly.

- Identification: This component focuses on identifying and assessing risks associated with tailings facilities. It recommends that companies conduct regular risk assessments to identify potential risks and take appropriate mitigation measures.

- Management and Response: This component provides guidance on the management and response to tailings-related incidents. It recommends that companies establish clear emergency response plans and procedures, including protocols for notification and communication.

- Design, Construction, Operation and Closure: This component provides guidance on the design, construction, operation and closure of tailings facilities. It recommends that companies apply best practices in these areas to ensure the safe and responsible management of tailings facilities.

- Monitoring: This component emphasizes the need for ongoing monitoring of tailings facilities to identify and address any issues that may arise. It recommends that companies establish monitoring programs tailored to each facility’s specific risks and characteristics.

- Review and Implementation: This component provides guidance on the review and implementation of the GISTM. It recommends that companies regularly review their tailings management practices against the GISTM and take appropriate measures to improve their performance.

Section 3: The Benefits of GISTM

The adoption of the GISTM can bring significant benefits to the mining industry, including:

- Improved Safety: The GISTM provides a comprehensive framework for the safe and responsible management of tailings facilities, helping to prevent catastrophic failures.

- Enhanced Environmental Performance: The GISTM guides the responsible management of tailings facilities, including mitigating environmental impacts.

- Increased Social Responsibility: The GISTM emphasizes the need for companies to take a responsible approach to tailings management, including engaging with local communities and other stakeholders.

- Improved Operational Efficiency: The GISTM guides best tailings management practices, helping companies optimize their operations and reduce costs.

Section 4: Conclusion

The Global Industry Standard on Tailings Management provides a comprehensive framework for tailings facilities’ safe and responsible management. It is designed to enhance tailings facilities’ safety, environmental and social performance worldwide. By adopting the GISTM, companies can benefit from improved security, enhanced environmental performance, increased social responsibility, and improved operational efficiency.

Efficient channel maintenance dredging for optimal waterway management – Neumann Dredging

The South Wavebreak Island on the Gold Coast of Australia is one of the most popular tourist attractions in the area. However, maintaining the navigation channels around the island requires constant maintenance to ensure safe passage for vessels. Neumann Dredging, a leading Australian dredging contractor, has been entrusted with the task of carrying out channel maintenance dredging in the South Wavebreak Island area. In this paper, we will explore the details of the project and the methods employed by Neumann Dredging to ensure its success.

Project Overview: The South Wavebreak Island channel maintenance dredging project was undertaken by Neumann Dredging in order to maintain the safe passage of vessels in the area. The project involved the removal of sand and silt from the navigation channels to maintain their designated depth and width. The project covered an area of approximately 28,000 square meters and required the removal of over 55,000 cubic meters of material.

Methodology: To achieve the project objectives, Neumann Dredging employed a cutter suction dredge (CSD), which is a specialized dredging vessel capable of cutting and removing hard materials such as sand, clay, and rock. The CSD used in the project was equipped with a powerful pump and suction head to remove the dredged material from the seabed. The dredged material was then transported to a designated disposal area.

One of the unique aspects of the South Wavebreak Island project was the use of an environmentally friendly dredging technique known as ‘rainbowing’. This technique involves the use of a high-pressure water jet to spray the dredged material onto the beach, where natural processes then redistribute it. This method eliminates the need for additional trucks or heavy machinery, thereby reducing the project’s carbon footprint.

Challenges: The South Wavebreak Island project presented several challenges to Neumann Dredging. The first challenge was the presence of sensitive environmental habitats around the project site, including seagrass meadows and coral reefs. To minimize the impact of the dredging on these habitats, Neumann Dredging worked closely with environmental experts and regulators to develop a dredging plan that minimized the impact on the surrounding ecosystem.

Another challenge was the presence of heavy marine traffic in the area, which posed a risk to both the dredging vessel and other vessels in the vicinity. To mitigate this risk, Neumann Dredging implemented strict safety measures, including the deployment of warning buoys and the use of spotters to monitor vessel movements in the area.

The South Wavebreak Island channel maintenance dredging project by Neumann Dredging was a successful endeavour that resulted in safe and reliable navigation channels around the island. The project’s success was due to the innovative methods employed by Neumann Dredging, including the use of a CSD and an environmentally friendly dredging technique. The project demonstrated Neumann Dredging’s commitment to delivering sustainable dredging solutions that minimize environmental impacts while ensuring the safe passage of vessels.

Clearing the Way for Clean Energy: Fly Ash Tailing Dredging by Neumann Dredging

As the world’s energy demand continues to grow, power stations have become an integral part of modern society. These facilities generate electricity using a variety of fuels, including coal. However, the combustion of coal produces waste byproducts, including fly ash. Fly ash is a fine powder that can contain toxic elements such as arsenic, lead, and mercury, making it hazardous to both human health and the environment. Therefore, proper management and disposal of fly ash is critical. One of the most effective solutions for managing fly ash tailings is through dredging, and Neumann Dredging is a leading provider of this service.

Understanding Fly Ash Tailings

Fly ash tailings are generated from the combustion of coal at power stations. This waste material is collected as slurry and transported to a tailings dam for storage. Over time, the tailings dam can become saturated, leading to potential environmental hazards. Therefore, it’s essential to effectively manage these tailings to ensure they don’t pose a risk to the environment and human health.

The Importance of Dredging Fly Ash Tailings

Dredging is one of the most effective solutions for managing fly ash tailings. The risk of environmental contamination is significantly reduced by removing the tailings from the dam and transporting them to a designated area for disposal. Dredging also ensures that the tailings are thoroughly mixed, preventing the formation of dust clouds that can pose health risks to the surrounding community.

Neumann Dredging’s Fly Ash Tailings Dredging Services

Neumann Dredging offers comprehensive fly ash tailings dredging services tailored to meet each client’s specific needs. Our experienced professionals use state-of-the-art equipment and innovative techniques to efficiently and effectively remove the tailings from the dam. We also ensure that the tailings are safely transported and disposed of in compliance with all relevant regulations.

The Benefits of Neumann Dredging’s Fly Ash Tailings Dredging Services O

your fly ash tailings dredging services offer a range of benefits to our clients. These include:

Improved Environmental Management: Our dredging services help reduce environmental contamination risk by safely removing and disposing of fly ash tailings.

Increased Operational Efficiency: Power stations can operate more efficiently by effectively managing fly ash tailings, reducing downtime and maintenance costs.

Compliance with Regulations: Our dredging services fully comply with all relevant regulations, ensuring our clients avoid costly fines and penalties.

Effective management of fly ash tailings is essential to ensuring the health and safety of the environment and surrounding communities. Dredging is one of the most effective solutions for managing fly ash tailings, and Neumann Dredging is a leading service provider. By partnering with us, power stations can ensure that their fly ash tailings are handled safely, efficiently, and in compliance with all relevant regulations.

Committed to excellence in safety, quality, and environmental management – Neumann Dredging

Neumann Dredging is a leading dredging contractor in Australia, known for its technical expertise and innovative solutions. In its commitment to safety, quality, and environmental sustainability, Neumann Dredging has achieved Sci Qual certification for several international standards.

AS/NZS 4801 Certification for Occupational Health and Safety – AS/NZS 4801 is an international standard for Occupational Health and Safety Management Systems, outlining the requirements for an effective safety management system. Neumann Dredging has achieved this certification, demonstrating its commitment to the safety and well-being of its team members, contractors, and the public.

ISO 45001 Certification for Occupational Health and Safety – ISO 45001 is another international standard for Occupational Health and Safety Management Systems, focusing on preventing work-related injury and ill health. By achieving this certification, Neumann Dredging has demonstrated its proactive approach to managing occupational health and safety risks and its commitment to continuous improvement.

ISO 9001 Certification for Quality Management – ISO 9001 is an international standard for Quality Management Systems, focusing on customer satisfaction and continuous improvement. By achieving this certification, Neumann Dredging has demonstrated its ability to consistently provide products and services that meet customer and regulatory requirements.

ISO 14001 Certification for Environmental Management – ISO 14001 is an international environmental management system standard outlining the requirements for an effective environmental management system. Neumann Dredging has achieved this certification, demonstrating its commitment to reducing its environmental impact and promoting sustainability.

Neumann Dredging’s achievement of Sci Qual certification for AS/NZS 4801, ISO 45001, ISO 9001 and ISO 14001 is a testament to its commitment to safety, quality, and environmental sustainability. These certifications demonstrate Neumann Dredging’s ability to consistently provide safe, high-quality, and sustainable dredging solutions while also reducing its environmental impact. Customers can trust Neumann Dredging’s commitment to excellence and its ability to deliver projects that meet the highest safety, quality, and sustainability standards.

Tailings dredging done right – Neumann Dredging is the name you can trust

Coal mining is one of the most critical industries in the world, and it provides energy to billions of people every day. However, coal mining also generates a lot of waste, including tailings, which can cause significant environmental damage if not properly managed. At Neumann Dredging, we provide effective and efficient coal mine tailings dredging services to help prevent such damage.

What are Coal Mine Tailings?

Coal mine tailings are the waste materials that are generated during the coal mining process. These materials are often mixed with water and chemicals, creating a slurry usually stored in large impoundments or tailings dams. Coal mine tailings can contain high levels of toxic substances, such as heavy metals and chemicals, which can leach into the environment and harm local ecosystems and human health.

Why are Coal Mine Tailings Dredging Necessary?

Coal mine tailings dredging is necessary to prevent environmental damage and reduce the risk of accidents at tailings dams. If not adequately managed, tailings can seep into groundwater, rivers, and streams, contaminating them with harmful chemicals and metals. Furthermore, tailings dams can fail and collapse, causing devastating environmental and human disasters, as seen in the Mount Polley mine disaster in British Columbia, Canada, in 2014.

How Does Neumann Dredging Conduct Coal Mine Tailings Dredging?

At Neumann Dredging, we use advanced dredging technology and equipment to safely and effectively remove coal mine tailings from impoundments and tailings dams. Our dredging services include the following:

- Dredging of tailings ponds, dams, and impoundments

- Dewatering of the tailings

- Processing of the tailings

- Sludge removal and disposal

- Site restoration

We work closely with our clients to develop a tailored solution that meets their specific needs, ensuring the efficient and effective removal of coal mine tailings. Our experienced team is committed to delivering high-quality services that adhere to the highest safety and environmental standards.

Why Choose Neumann Dredging for Coal Mine Tailings Dredging?

Neumann Dredging is a leading dredging contractor with extensive experience in the mining industry. We have a proven track record of delivering safe, efficient, and cost-effective coal mine tailings dredging services. Our team of experts is highly skilled in all aspects of tailings dredging, and we use the latest technology and equipment to ensure optimal performance and safety.

Furthermore, we are committed to sustainable practices and reducing the environmental impact of our operations. Our comprehensive environmental management systems and quality control measures ensure that all of our work is conducted in accordance with the highest environmental and safety standards.

Coal mine tailings dredging is essential to prevent environmental damage and reduce the risk of accidents at tailings dams. At Neumann Dredging, we provide efficient and effective coal mine tailings dredging services tailored to our client’s specific needs. With our advanced technology and equipment, experienced team, and commitment to sustainability, we are the best choice for coal mine tailings dredging services.