Mining Dredging Projects

Dredging Solutions for Sustainable Mining and Resource Management!

High Quality Sands – Coffs Harbour

Nav. Channel Maintenance,

River and Waterways Dredging,

Beach Nourishment.

Neumann Dredging was contracted by the client High Quality Sands from Coffs Harbour, however the project took place at Repton in NSW, whereby sand was dredged from Bellinger River to the client's concrete processing plant.

Liddell Power Station Fly Ash Dredging

Tailings Storage Facility (TSF) Maintenance

AGL Macquarie engaged Neumann Contractors to dredge fly ash from a temporary storage facility to a permanent storage location at the Liddell Power Station. Neumann Contractors designed and built 450mm cutter suction dredge the Nu Bounty for the project in conjunction with a 2,000 hp, Neumann built, 450mm booster station working 7 days per week.

Bellinger River Resource Dredging

Resource Dredging,

Sand Mining,

River and Waterways.

Coarse river sand from mined from the Bellinger River waterways in Coffs Harbour for HQ Sands using the Nu Discovery Cutter Suction Dredge. The Neumann Equipment built Nu Discovery cutter suction dredge pumped the sand approximately 1km and discharged it directly to the processing plant at their facility in Repton.

Hellyer Gold Dredge Hire

Dredge Dry Hire,

Mud/Silt/Sediment Removal / Relocation.

Hellyer Gold Mines hired a Neumann Contractors' designed and built 250mm cutter suction dredge, the ‘Nu-Investigator’ for 12 months to supplement the operations of their existing dredge in the site's tailings ponds. The hire agreement was a dry hire arrangement with Neumann Contractors providing experienced operators in the initial phase to train Hellyer’s operators in running the dredge.

Bulga Mine Dredge Trial

Coal Tailings Relocation,

Mud Removal /Relocation.

Bulga Coal Management engaged Neumann Dredging to undertake a dredging trial to determine the feasibility and confirm the design of the tailings delivery system for a significant coal tailings relocation project. The test successfully demonstrated that the coal tailings could be efficiently and consistently pumped at slurry density concentrations from 0% to 45% using the Nu-Endeavour cutter suction dredge.

Cudgen Lakes Resource Dredging

Resource Dredging,

Sand Mining.

370,000 m3 of sand from Cudgen Lakes to raise the existing surface level of the adjacent Kingscoast Estate by 3m. The sand was dredged from Cudgen Lakes Sand Quarry by Neumann Dredging designed and built 450mm bucketwheel cutter suction dredge the ‘Nu-Bounty’ and then pumped up to 2,000m under a busy road to the site.

Monreagh Dam Tailings Dredging

Tailings Storage Facility (TSF) Maintenance,

Sediment Removal.

The dredging works at Monreagh Mine involves the removal the sediment from the nominated dredge area in the pond at the site in Miles with the use of our 250mm cutter suction dredge the Nu Discovery. The dredge will be used to transport the material through a combination of 246 mm (ID) floating and land-based pipeline to the nominated disposal area in the opposite end on the pond.

Caval Ridge Tailings Dredging

Mud/Silt/Sediment Removal / Relocation

The BHP Mitsubishi Alliance(BMA) contracted Neumann Dredging to remove 475,00m3 of mud from the open cut coal mine as part of the preparation for reopening the pit. For some time, the pit has been disused, and over that time, surface runoff caused erosion, which meant material had accumulated on the pit floor.

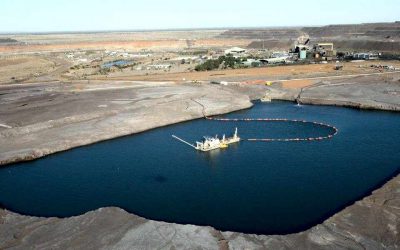

Ok Tedi Tailings Dredging

Mining Dredging

Dredge Nu Explorer was specifically built to enable simple and cost effective transport to the most remote locations. Able to fit into two standard 40 foot open top containers, Nu Explorer was dispatched to the Ok Tedi mine, situated at an elevation of 1700m in the remote Western Highlands of PNG.

Corridor Sands Resource Dredging

Resource Dredging,

Sand Mining.

Corridor Sands pride themselves on supplying premium quality sands, excellent customer service and fast, efficient loading. The cutter suction dredge Nu Ultra has been working permanently at Corridor Sands since 2009. The Nu-Ultra efficiently supplies raw sand to the production plant. As a result, a range of high-quality sand products can be produced.

Ernest Henry Mine Tailings Dredging

Tailings Removal/Transfer,

Tailings Reprocessing,

Re-Mining.

Ernest Henry Mining commissioned our 300mm CSD Nu Compact to reprocess/remine the tailings from the Tailings Storage Facility (TSF) to recover magnetite. The Nu Compact pumped the reclaimed tailings via a 1000 metre long HDPE pipeline directly into a processing circuit in which the magnetite was concentrated. The dredge operated on a 24/ basis while maintaining a consistent feed density to the processing plant.

Cadia Gold Mine Tailings Dredging

Mud/Silt/Sediment Removal / Relocation,

Tailings Storage Facility (TSF) Maintenance.

Newcrest Mining Ltd contracted Neumann Dredging to dredge the process water pond at Cadia Gold Mine in Orange, N.S.W. The dredge used for the project was the Nu Investigator cutter suction dredge. The dredge was fitted with high-pressure water jets to loosen the material.

Moura Mine Tailings Dredging

Navigational Channel Maintenance

Nu-Endeavour was chosen to reclaim coal tailings from the Moura 2C pit. The plant processed these tailings to recover the fine coal lost in earlier operations, and it was part of a program to empty the pit to enable ongoing mining underground from the pit floor. The client required the dredge to produce 450 tonnes per hour of coal tailings and pumped distances of up to 2.5km to the processing plant.

Penrith Lakes Tailings Dredging

Tailings Storage Facility (TSF) Maintenance

The project involved dredging of approximately 1,300,000m3 of sand, silts and clays from a central tailings storage facility to a land reclamation site 4.4 km away. The materials are being placed in a manner which enabled the coarser fractions of the tailings to be separated from the silts and clays.

Superior Coal Tailings Dredging

Tailings Storage Facility (TSF) Maintenance

Neumann Dredging were engaged as Dredging Contractors to carry out the dredging works to clear a pond 150 meters wide, 650 meters long of coal tailings that washed in over several years. The coal tailings, ranging from fine silt to approximately 70mm in size, were pumped to a screening and washing plant for recovery and then placed in stockpiles in the coal storage area.

Liddell Bottom Ash Dredging

Tailings Storage Facility (TSF) Maintenance

AGL Macquarie engaged Neumann Contractors to dredge coarse bottom ash (Clinker) from a temporary storage facility to a permanent storage location at the Liddell Power Station. The dredging works consisted of pumping approx. 130,000 m3 of bottom ash (clinker), a distance of 650m with an elevation of 20 metres to a permanent storage facility.