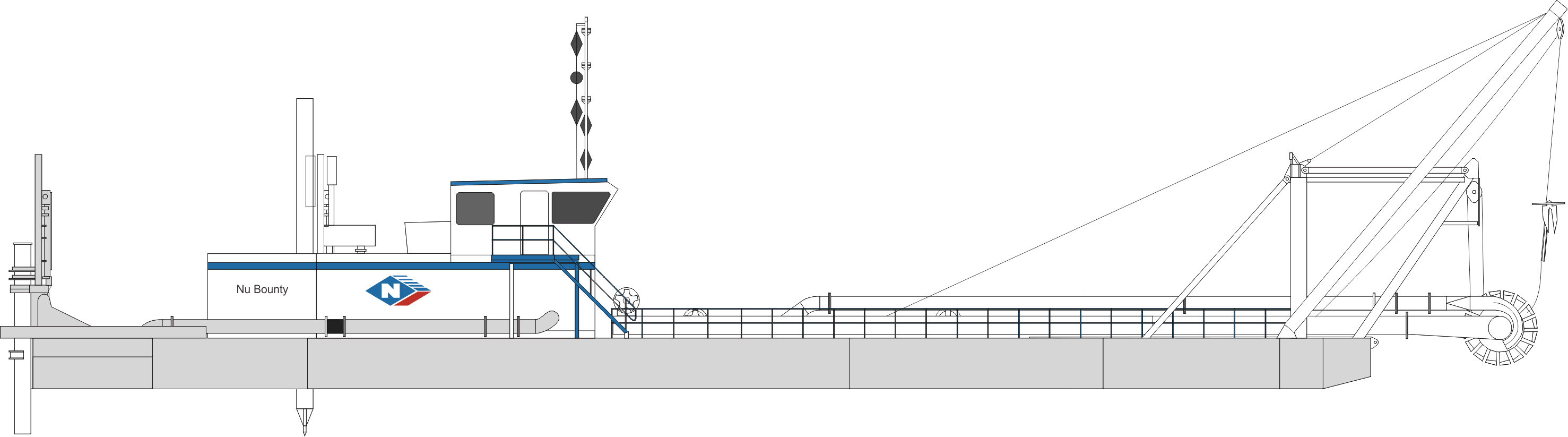

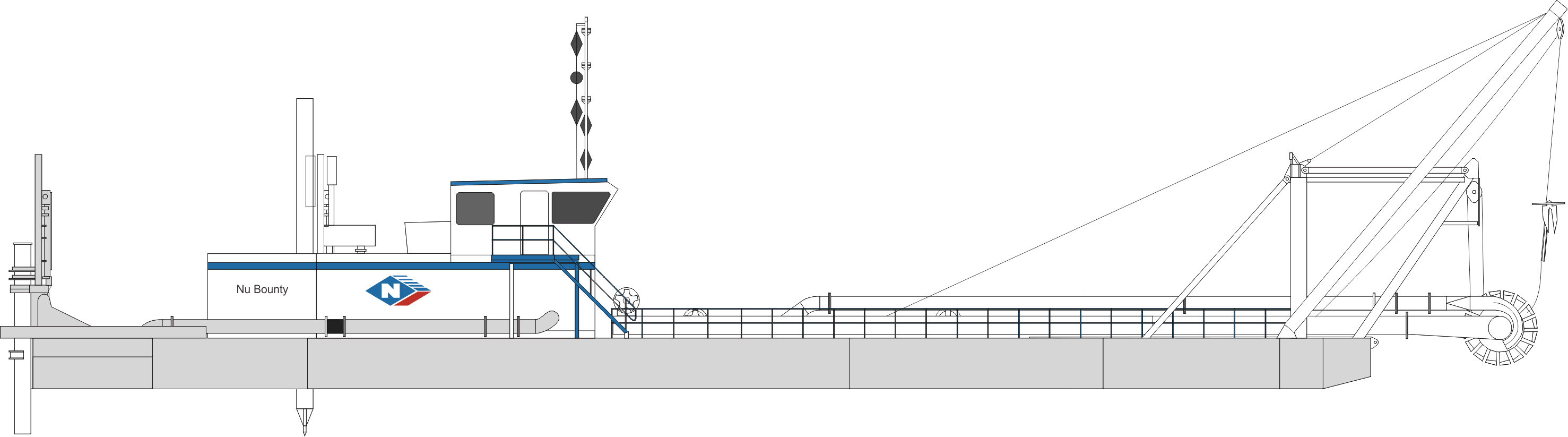

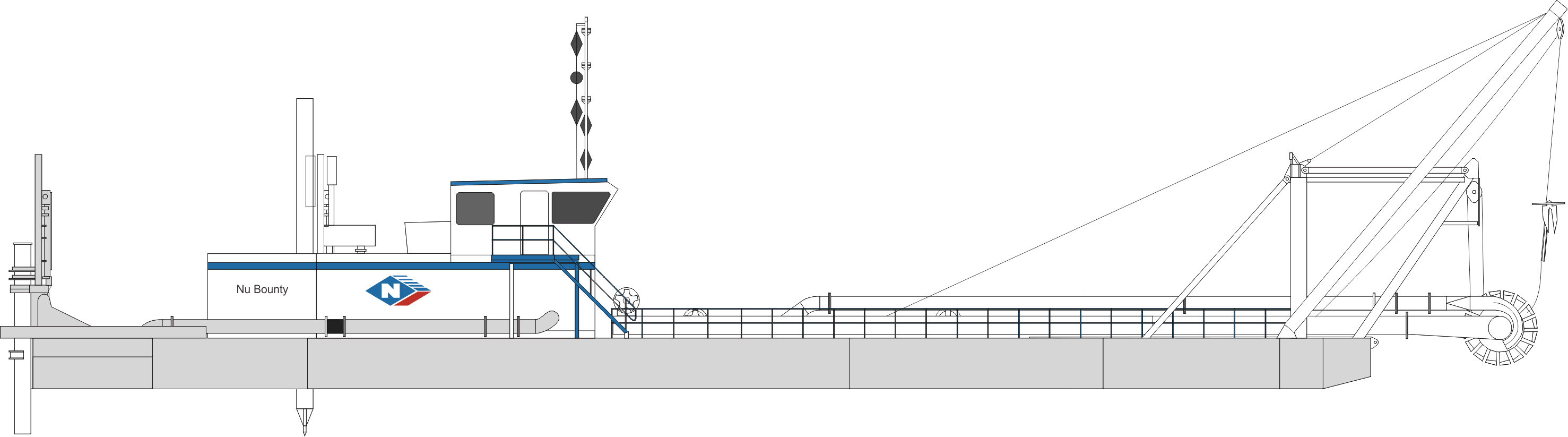

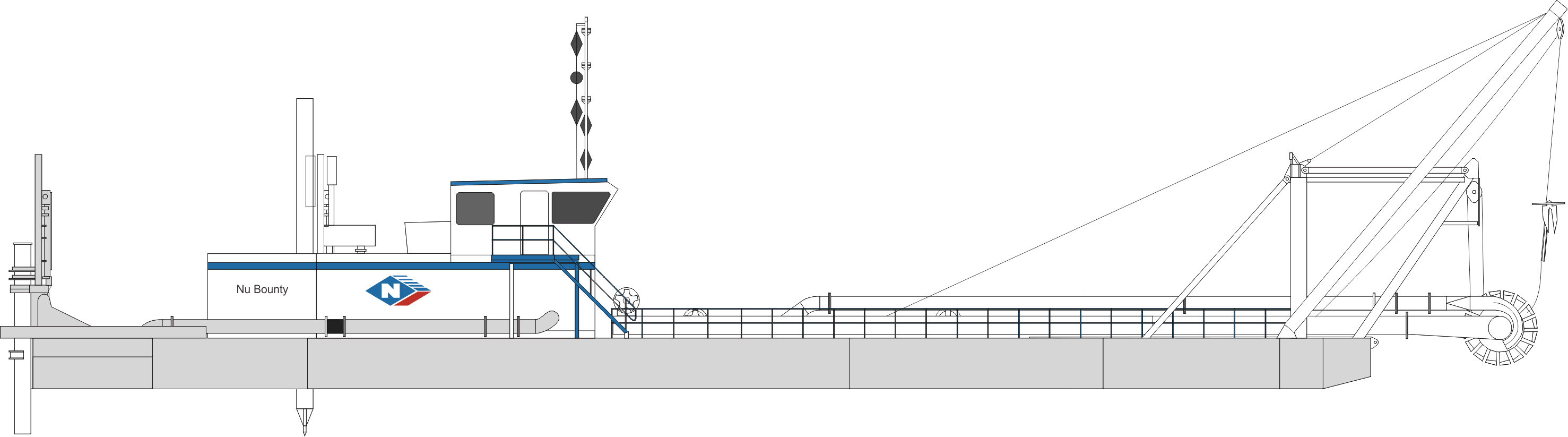

Nu Bounty

Cutter Suction Dredge

Nu Bounty Cutter Suction Dredge

The Nu Bounty Cutter Suction Dredge is a Neumann Series 350 Series dredge built by Neumann Equipment in the 1980s. Since then, it has undergone numerous refurbishments, upgrades and improvements. The operational expertise built on our contract dredging experience enables us to improve our equipment constantly. This culture of innovation gives us the leading edge as dredging contractors of choice.

The Nu Bounty has evolved into a high technology cutting and recovery machine and has a well-earned reputation for performance and reliability in channel maintenance dredging, capital works marine dredging, and mining and resource dredging. The dredge can operate in short or long configurations.

The dredge is demountable and can be cost-effectively transported to remote sites around Australia and overseas. In addition, the use of this dredge has proven to be a safe and cost-effective method on mine sites for the relocation or reprocessing of tailings.

The Nu Bounty Cutter Suction Dredge has been successfully used to remove sand, gravels, clays, muds, silts, slimes, weathered rock, and mine tailings.

In harbour and river works, where the cutter suction dredge might encounter a variety of natural and dumped materials, Neumann dredges have proven their versatility.

Neumann’s extensive dredging experience makes our dredges highly suited for various material types often encountered in flood prevention and environmental rehabilitation works.

The Nu Bounty has worked on the following Projects:

Nu Bounty Cutter Suction Dredge Specifications

Nu Bounty CSD Specifications

| Length Overall (short/long) | 33.4/41.30m |

| USL Class | 2E (smooth waters) |

| Owners Name | Neumann Dredging |

| Owners Address | Nuban St, Currumbin Qld 4223 |

| Homeport | Currumbin, Qld |

| Builder | Neumann Equipment |

| Nominal Production Rate | 650m3/hr |

| Total Power | 1,454 kW (1,950 hp) |

| Power to Pumps | 1,044 kW (1,400 hp) |

| Pipeline Diameter | 500 mm |

| Minimum Digging Depth (min/max) | 2.5m |

| Digging Depth (short/long) | 15m/22m |

| Bucketwheel Diameter | 2.4m |

| Hull Material | Steel |

| Superstructure Material | Steel/Aluminium |

| Gross Weight (short/long) | 220/240 Tonnes |

| Ship Type | Dredge – Non Self-Propelled |

| Hull/Deck Colour | Grey/Grey |

| Superstructure Colour | White with Blue Trim |

The Nu Bounty has worked on the following Projects:

Liddell Power Station Fly Ash Dredging

Tailings Storage Facility (TSF) Maintenance

AGL Macquarie engaged Neumann Contractors to dredge fly ash from a temporary storage facility to a permanent storage location at the Liddell Power Station. Neumann Contractors designed and built 450mm cutter suction dredge the Nu Bounty for the project in conjunction with a 2,000 hp, Neumann built, 450mm booster station working 7 days per week.

Sydney Water Desalination Project

Capital Works Dredging,

Ports and Harbour,

River and Waterways Dredging.

Dredging works associated with the Botany Bay pipeline crossing, which was part of the construction of Sydney’s DeSal plant at Kurnell, Southern Sydney. When completed water from the desalination plant will be piped to the City Water Tunnel at Erskineville. This is part of the Potts Hill Water system, which services areas south of Sydney Harbour, to Bankstown in the west and Sutherland in the south.

Caval Ridge Tailings Dredging

Mud/Silt/Sediment Removal / Relocation

The BHP Mitsubishi Alliance(BMA) contracted Neumann Dredging to remove 475,00m3 of mud from the open cut coal mine as part of the preparation for reopening the pit. For some time, the pit has been disused, and over that time, surface runoff caused erosion, which meant material had accumulated on the pit floor.

Port Kembla Tug Berth Dredging

Capital Works,

Ports and Harbour,

Navigational Channel Maintenance.

Neumann Dredging were engaged as dredging contractors for McConnell Dowell for the dredging works to construct a new tug boat berthing area for Port Kembla. The new tug berth area is to protect the tugs from extreme weather conditions by the means of extended break water out into the existing harbour.

Cudgen Lakes Resource Dredging

Resource Dredging,

Sand Mining.

370,000 m3 of sand from Cudgen Lakes to raise the existing surface level of the adjacent Kingscoast Estate by 3m. The sand was dredged from Cudgen Lakes Sand Quarry by Neumann Dredging designed and built 450mm bucketwheel cutter suction dredge the ‘Nu-Bounty’ and then pumped up to 2,000m under a busy road to the site.

Port Botany Container Terminal

Capital Works,

Ports and Harbours,

Navigation Channel Maintenance.

Port Botany Container Terminal Expansion was a major infrastructure project for the Sydney Port Corporation on the North Eastern end of Botany Bay, South Sydney N.S.W. The project was for the expansion of the existing container port terminal and involved capital dredging and land reclamation. Neumann Dredging employed their 450mm dredge NuBounty and 250mm dredge Nu Enterprise.