Dredging

Dredging Solutions Tailored to Your Project!

Neumann Dredging: Pioneering in Contract Dredging for Over 70 Years

With a legacy spanning over seven decades, Neumann Dredging stands at the forefront of contract dredging and mining. Our journey began in the 1950s, pioneering the development of the first dredges designed specifically for mineral sand mining.

Our fleet of advanced dredging equipment is renowned for its exceptional reliability and performance, catering to both marine and mining sectors. These state-of-the-art dredges are not only versatile but also readily transportable, making them ideal for projects in remote locations across Australia and overseas.

Dredging with Neumann isn’t just about efficiency; it’s a commitment to safety and cost-effectiveness, especially in the transportation and reprocessing of tailings.

Our wealth of experience in contract dredging is matched by our dedication to continual improvement and innovation. This approach underpins our reputation as Australia’s leading dredging contractors, setting industry standards in both equipment and service.

Dredges

Dredging Equipment

Recent Capital Works Dredging Projects

Sydney Water Desalination Project

Capital Works Dredging,

Ports and Harbour,

River and Waterways Dredging.

Dredging works associated with the Botany Bay pipeline crossing, which was part of the construction of Sydney’s DeSal plant at Kurnell, Southern Sydney. When completed water from the desalination plant will be piped to the City Water Tunnel at Erskineville. This is part of the Potts Hill Water system, which services areas south of Sydney Harbour, to Bankstown in the west and Sutherland in the south.

Kingscoast Estate Project

Resource Mining,

Hydraulic Sand Transfer,

Civil Works.

The project was to hydraulically place 370,000 m3 of sand to raise the surface level of the Kingscoast Estate by 3 metres. The team dredged the sand from an adjacent sand quarry by the Nu Bounty, a 450mm bucketwheel cutter suction dredge combined with a 500mm, 2,000 hp booster pump. The slurry was pumped distances up to 2,000m through a 560mm poly pipeline to the estate. We achieved considerable savings and advantages over traditional methods.

Gold Coast Convention Centre

River and Waterways Dredging,

Land Reclamation,

Capital Works,

Civil Works.

Neumann Contractors was awarded the civil works contract for the Gold Coast Convention and Exhibition Centre project. The relocation of the major waterway, essential services and environmental issues presented some demanding challenges. This project brought its unique complexities as it involved several different concurrent tasks. Neumann Contractors acknowledge the civil work challenges were managed successfully due to the team approach with the builders and consulting engineers.

Port Botany Container Terminal

Capital Works,

Ports and Harbours,

Navigation Channel Maintenance.

Port Botany Container Terminal Expansion was a major infrastructure project for the Sydney Port Corporation on the North Eastern end of Botany Bay, South Sydney N.S.W. The project was for the expansion of the existing container port terminal and involved capital dredging and land reclamation. Neumann Dredging employed their 450mm dredge NuBounty and 250mm dredge Nu Enterprise.

Recent Channel Maintenance Dredging Projects

Recent Mining/Tailings Dredging Projects

Liddell Power Station Fly Ash Dredging

Tailings Storage Facility (TSF) Maintenance

AGL Macquarie engaged Neumann Contractors to dredge fly ash from a temporary storage facility to a permanent storage location at the Liddell Power Station. Neumann Contractors designed and built 450mm cutter suction dredge the Nu Bounty for the project in conjunction with a 2,000 hp, Neumann built, 450mm booster station working 7 days per week.

Bellinger River Resource Dredging

Resource Dredging,

Sand Mining,

River and Waterways.

Coarse river sand from mined from the Bellinger River waterways in Coffs Harbour for HQ Sands using the Nu Discovery Cutter Suction Dredge. The Neumann Equipment built Nu Discovery cutter suction dredge pumped the sand approximately 1km and discharged it directly to the processing plant at their facility in Repton.

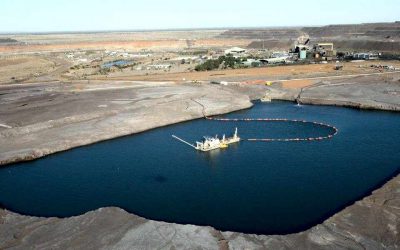

Ernest Henry Mine Tailings Dredging

Tailings Removal/Transfer,

Tailings Reprocessing,

Re-Mining.

Ernest Henry Mining commissioned our 300mm CSD Nu Compact to reprocess/remine the tailings from the Tailings Storage Facility (TSF) to recover magnetite. The Nu Compact pumped the reclaimed tailings via a 1000 metre long HDPE pipeline directly into a processing circuit in which the magnetite was concentrated. The dredge operated on a 24/ basis while maintaining a consistent feed density to the processing plant.

High Quality Sands – Coffs Harbour

Nav. Channel Maintenance,

River and Waterways Dredging,

Beach Nourishment.

Neumann Dredging was contracted by the client High Quality Sands from Coffs Harbour, however the project took place at Repton in NSW, whereby sand was dredged from Bellinger River to the client's concrete processing plant.