Understanding Channel Maintenance Dredging

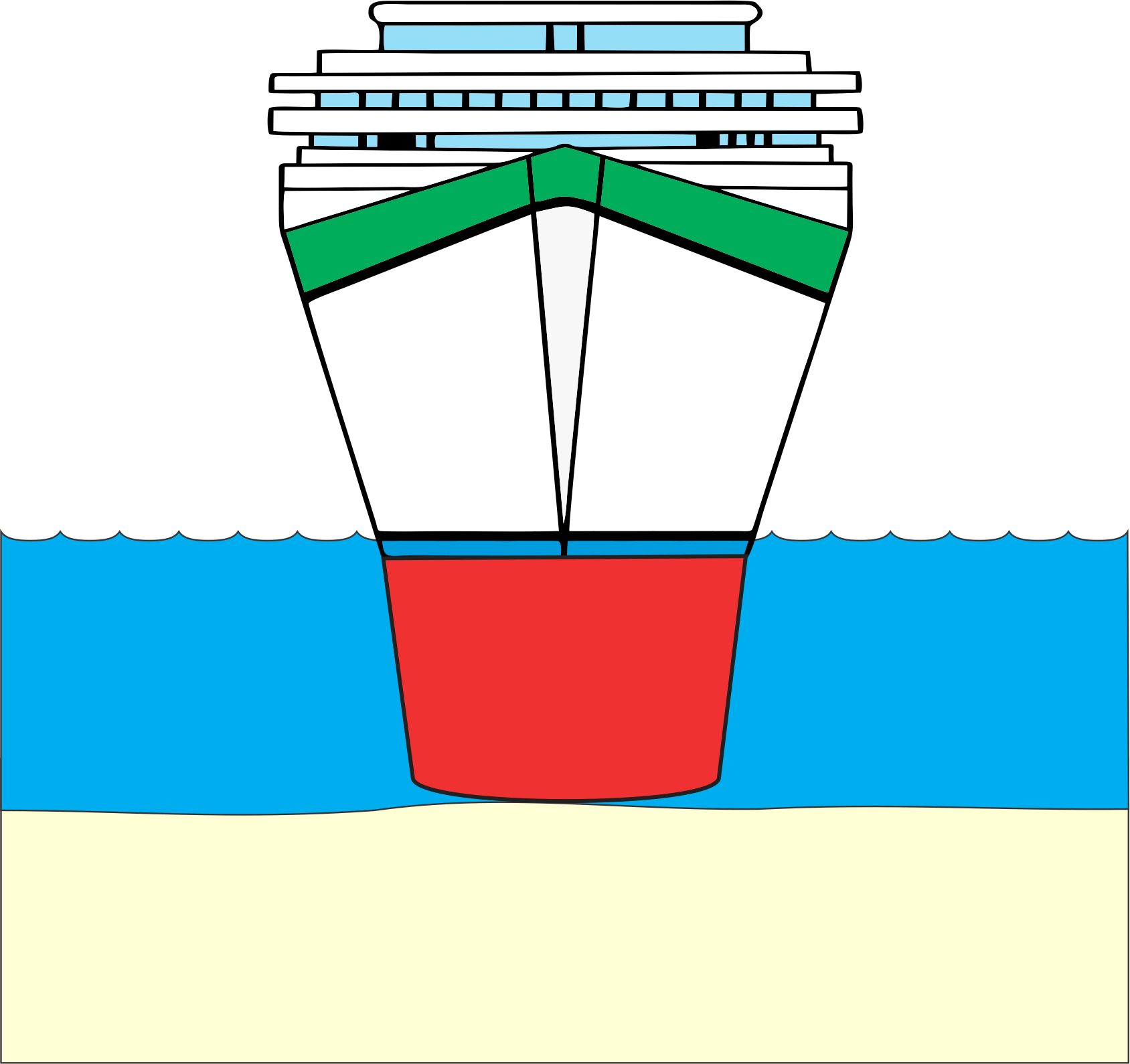

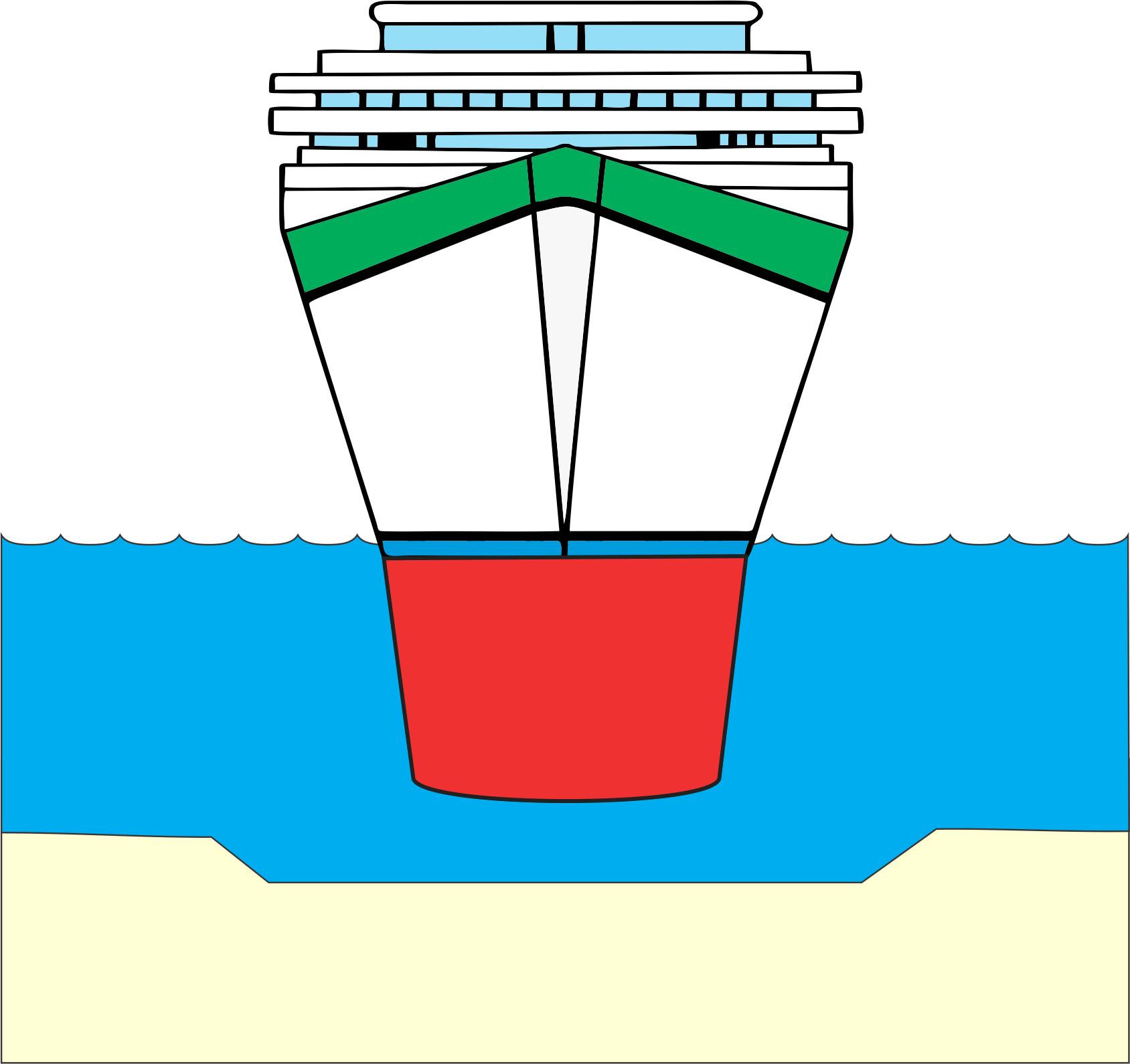

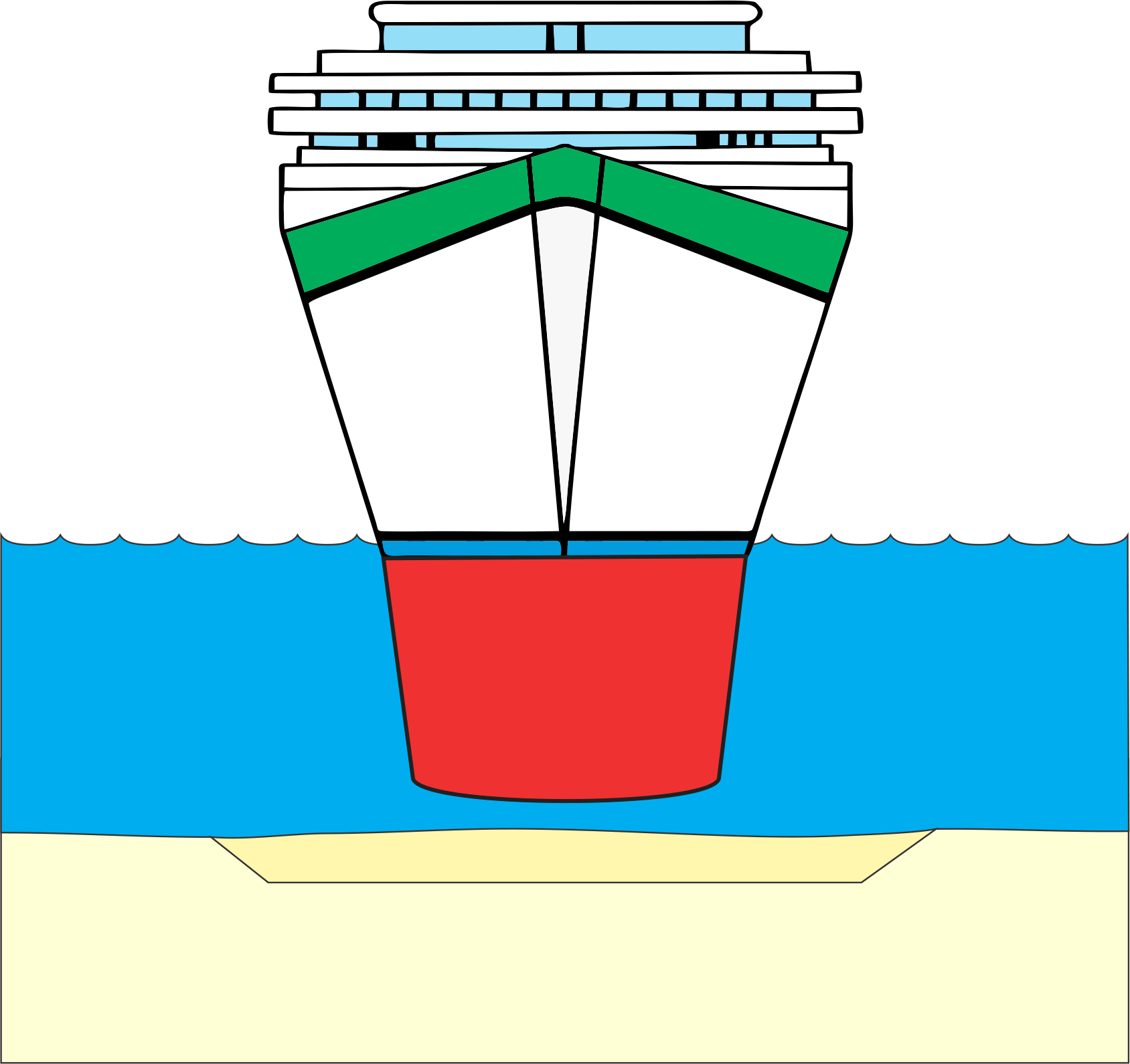

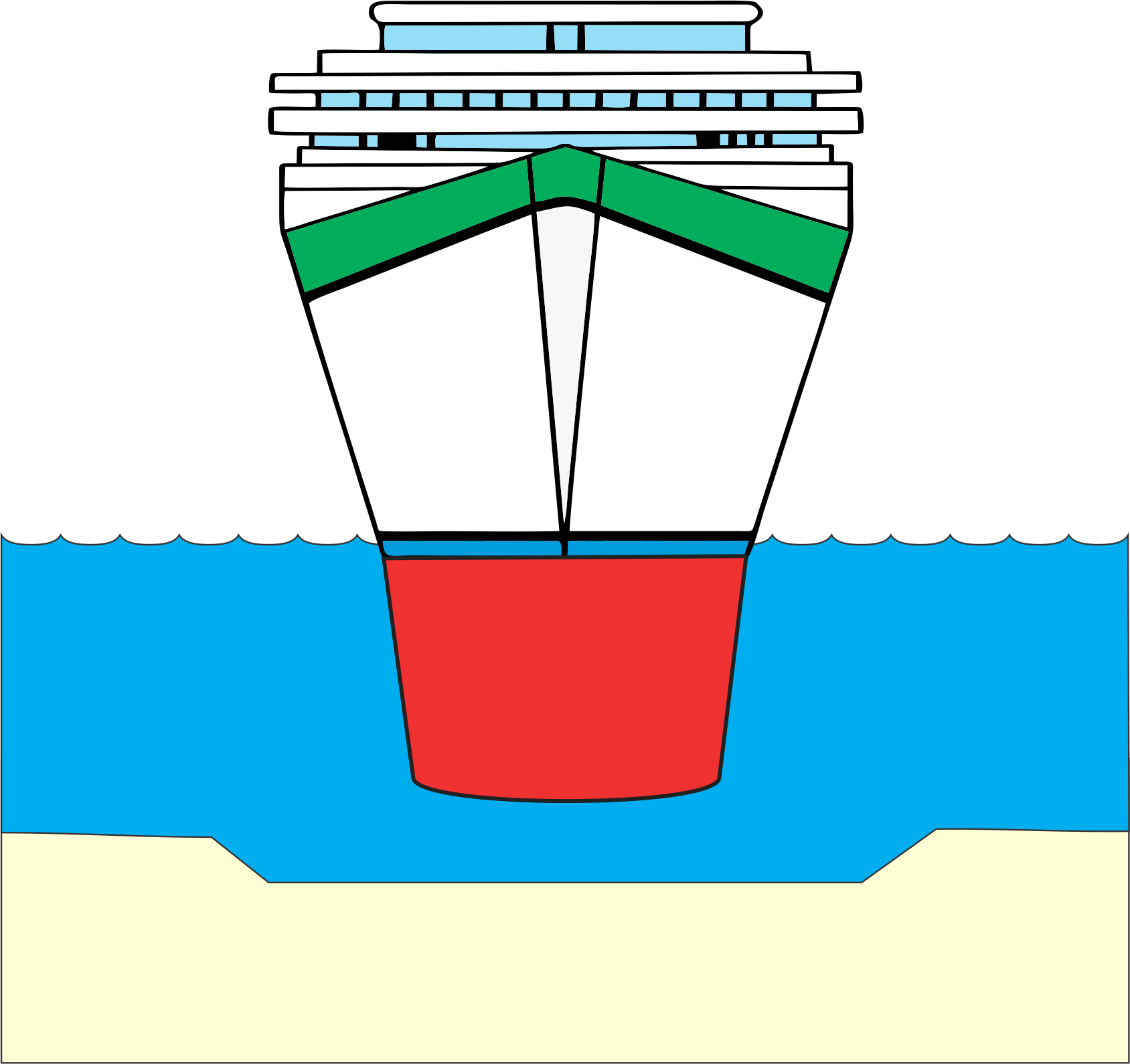

Channel maintenance dredging, a vital process for waterway safety, involves the removal of accumulated sand and sediment in navigational channels, berths, swing basins, and approaches. This build-up, often resulting from tidal movements, wave actions, and various weather conditions, poses significant risks for vessel navigation. Ignoring it can lead to severe consequences, including environmental harm, property damage, or, in extreme cases, loss of life.

Why Regular Maintenance Dredging is Crucial

To ensure our waterways remain safely navigable, regular maintenance dredging is indispensable. Ports, harbours, and channels undergo routine sediment removal to preserve their depth and functionality. Interestingly, the extracted sediments often find new life in beach nourishment or as valuable commercial products.

Methods of Conducting Maintenance Dredging

Maintenance dredging, a critical component of waterway management, involves several sophisticated techniques, each tailored to specific requirements and environmental conditions. Here’s a closer look at the primary methods:

- Trailing Suction Hopper Dredges – These are versatile, ship-like vessels equipped with full sailing capabilities, enabling them to navigate to the dredging site independently. They are designed to self-load and unload sediment and debris. The key component is a suction pipe, fitted with a drag head, which extends to the seabed. This drag head collects sediment as the ship moves, storing it in the hopper on board. Once filled, these dredges transport the sediment to designated disposal or treatment sites. This method is especially effective for larger projects and open waters due to their high capacity and mobility.

- Grab Excavation Dredging – Grab dredging uses a crane equipped with a grab or clamshell bucket to scoop sediment from the waterway’s bottom. This method is particularly useful for targeted dredging in confined spaces or areas with hard-to-reach debris. The grab can be precisely controlled to remove sediment from specific areas, making it ideal for maintenance work around piers, docks, and other structures. It’s often used in conjunction with other dredging methods to clear particular patches of sediment that are too dense or compacted for suction methods.

- Cutter Suction Dredges – Cutter suction dredges are powerful, stationary dredging systems. They use a rotating cutter head to dislodge and break up compacted sediment, which is then sucked up through a suction pipe. This method is highly efficient for hard and compacted materials, often found in riverbeds or near industrial sites. Cutter suction dredges are anchored in place during operation and require a pipeline to transport the dredged material to the disposal site. This method is known for its precision and effectiveness in maintaining the depth and profile of navigation channels and berths.

By understanding and implementing these effective maintenance dredging strategies, we can ensure the safety and navigability of our waterways. Each method has its specific applications and advantages, making them suitable for different dredging needs. The choice of method depends on various factors, including the type of sediment, the depth and width of the channel, environmental considerations, and the proximity to sensitive habitats. Properly executed, maintenance dredging not only safeguards our waterways but also helps protect the environment and supports commercial activities through the reuse of dredged materials.