Tug Berth & Channel Maintenance Dredging for Gladstone Ports Corporation

Scope of Works

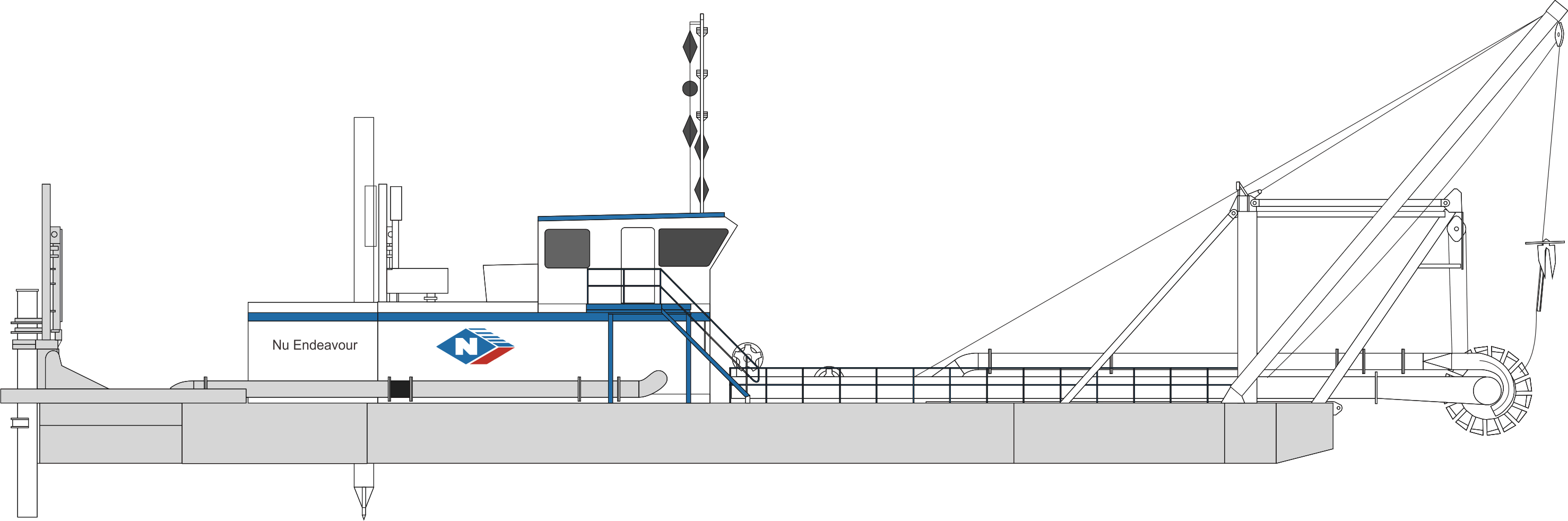

Neumann Dredging’s scope included the dredging of approximately 300,000 m3 from the Gladstone Harbour to clear material for a new tug berth area. The dredging of very hard clays, cobbles, gravel, and coarse river sands from the tug berth area. The material was pumped 1200 meters through a 400mm pipe and a booster pump to a stockpile area.

The operation was completed on a 24 hour, seven day week basis.

Innovations

Neumann Contractors experimented with various diameter bucket wheels, positioning cutter teeth for better performance from the dredge and pumps because of the indifference of material types on the project. Reduced discharge pipe to deposit material further away in the fill area—different techniques in batter cutting due to the material types.

Challenges

- Weather and sea state conditions.

- Dredging unpredictable material. Very stiff clays, gravel, cobbles and course river sands.

- Wear and tear on machinery and equipment.

- Strict dredging tolerances and program.

- Dealing with other marine vessels.