Dredge Trial at Bulga Mine

Overview of Project

Bulga Coal Management engaged Neumann Dredging to undertake a trial to determine the feasibility and confirm the design of the tailings delivery system for a significant coal tailings relocation project.

Scope of Works

The dredge trial scope included:

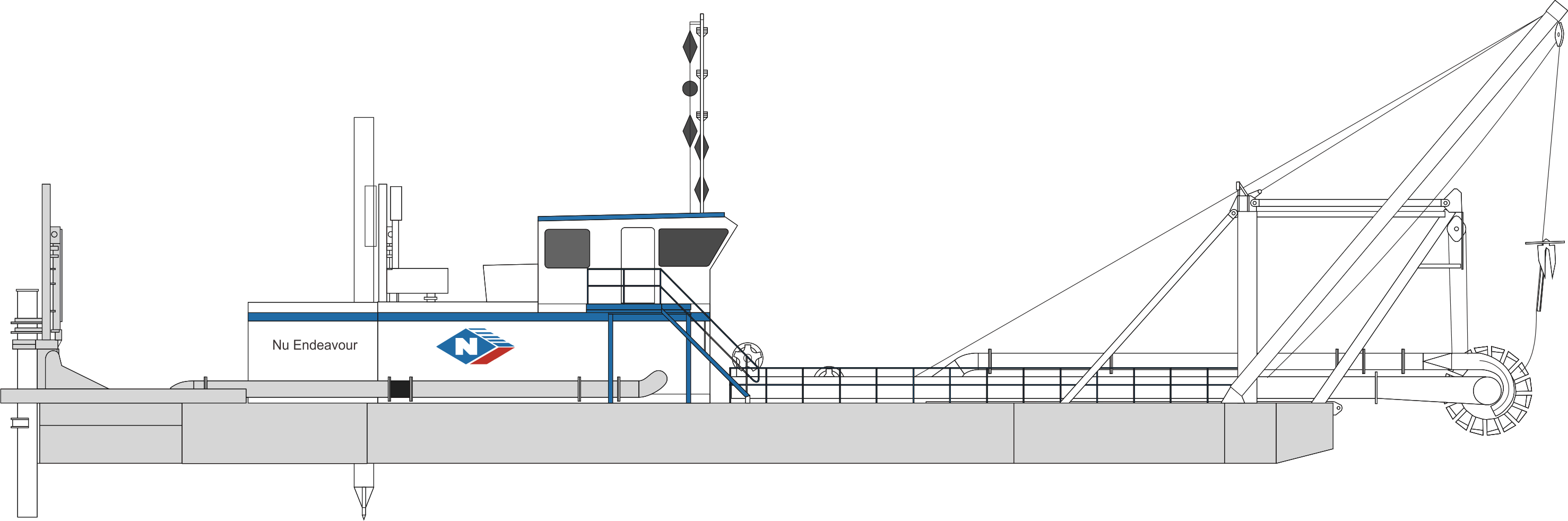

- Modifying the ‘Nu-Endeavor’ from an anchor boom and spud-controlled dredge to a three-wire dredge,

- Testing whether the tailings material could support the use of anchor booms and spuds,

- Testing shore-based anchoring options if the tailings could not support anchors,

- We are testing a range of pumping densities to confirm the overall system design,

- Confirm the maximum slurry density the dredge could achieve.

Challenges

The free-flowing nature of the coal tailings material proved challenging during the trial. However, we learned valuable lessons that would be beneficial in the long term.

Innovations

Custom design and fabrication of a stern winching system to replace the rear spuds for the 220t dredge.

Outcomes

The trial successfully demonstrated that the coal tailings could be efficiently and consistently pumped at slurry density concentrations from 0% to 45% using the cutter suction dredge the ‘Nu-Endeavour.